The multimeter can measure direct current, direct voltage, alternating voltage, and resistance. Some models can also measure power, inductance, and capacitance, making it one of the most commonly used instruments by electricians.

1. How to Use the Multimeter

(1) Ensure the terminal (or socket) selection is correct

The red probe must be connected to the red terminal (or the socket marked with “+”). The black probe should connect to the black terminal (or the socket marked with “-“). Some multimeters have measurement terminals for AC and DC at 2500 volts. When using, the black probe remains connected to the black terminal (or the “-” socket), and the red probe connects to the 2500-volt terminal (or socket).

(2) Ensure the switch position is correct

Rotate the switch to the required position based on the measurement type. For current measurement, switch to the corresponding current range; for voltage, switch to the corresponding voltage range. Some multimeters have two switches on the panel: one for selecting the measurement type and the other for selecting the measurement range. First, select the measurement type, then the measurement range.

(3) Choose the appropriate range

Based on the approximate range of the measurement, set the switch to the appropriate range for that type. When measuring voltage or current, it is best to keep the pointer within one-half to two-thirds of the range for more accurate readings.

(4) Read the measurement correctly

The multimeter’s scale has many scales that correspond to different measurement objects. Therefore, when measuring, read the value on the corresponding scale while also paying attention to the scale reading and range to avoid errors.

(5) Correct use of the ohm range

① Select the appropriate range:

When measuring resistance, choose a range that allows the pointer to rest in a less dense part of the scale. The closer the pointer is to the middle of the scale, the more accurate the reading; the further left, the denser the scale lines, the less accurate the reading.

② Zeroing:

Before measuring resistance, touch the two probes together and turn the “zeroing knob” until the pointer points to the zero position on the ohm scale. This step is called zeroing the ohm range. Each time you switch ohm ranges, repeat this step to ensure measurement accuracy. If the pointer cannot reach zero, it indicates that the battery voltage is low and needs to be replaced.

③ Do not measure resistance while powered:

When measuring resistance, the multimeter is powered by a battery. The resistance being measured must not be powered to avoid damaging the meter. During the use of the ohm range, do not short-circuit the two probes to avoid wasting battery.

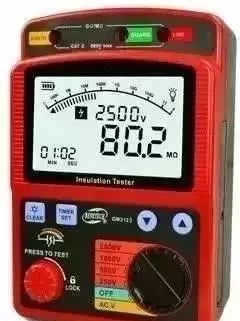

The megohmmeter, commonly known as a shake meter, is used to measure high resistance and insulation resistance, with its unit of measurement being megohms (MΩ), hence the name megohmmeter. There are many types of megohmmeters, but their functions are generally similar.

Hand-cranked megohmmeter

Electronic megohmmeter

1. Selection of Megohmmeter

The voltage rating of the megohmmeter should be higher than the insulation voltage rating of the object being tested. Therefore, when measuring the insulation resistance of devices or lines with a rated voltage below 500V, a 500V or 1000V megohmmeter can be used;

When measuring insulation resistance for devices or lines with a rated voltage above 500V, a 1000-2500V megohmmeter should be selected; when measuring insulators, a 2500-5000V megohmmeter should be used.

Generally, when measuring the insulation resistance of low-voltage electrical equipment, a megohmmeter with a range of 0-200MΩ can be chosen.

2. Method for Measuring Insulation Resistance

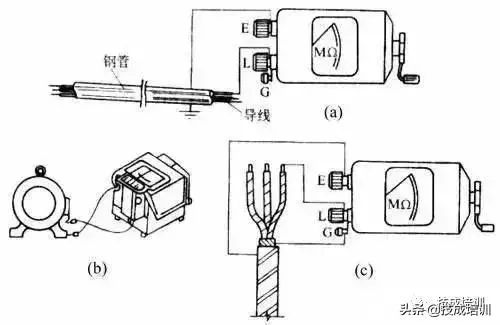

The megohmmeter has three terminal posts. The two larger upper terminal posts are marked “Ground” (E) and “Line” (L), while the smaller lower terminal post is marked “Protective Ring” (or “Shield”) (G).

(1) Insulation resistance of the line to ground

Connect the “Ground” terminal post (E) of the megohmmeter securely to ground (generally to a grounding body), and connect the “Line” terminal post (L) to the line being tested, as shown below.

After connecting, turn the megohmmeter clockwise, gradually increasing the speed, maintaining it at about 120 revolutions per minute. When the speed stabilizes, the pointer will also stabilize, and the value indicated by the pointer will be the insulation resistance of the object being measured.

In actual use, the E and L terminal posts can also be connected in any order; E can connect to the object being tested, and L can connect to the grounding body (i.e., ground), but the G terminal post must not be connected incorrectly.

(a) Measuring the insulation resistance of the line

(b) Measuring the insulation resistance of the motor

(c) Measuring the insulation resistance of the cable

(2) Measuring the insulation resistance of the motor

Connect the E terminal post of the megohmmeter to the motor casing (i.e., ground), and connect the L terminal post to one phase of the motor winding, as shown above. The insulation resistance value obtained is the ground insulation resistance value of that phase.

(3) Measuring the insulation resistance of the cable

When measuring the insulation resistance between the conductive core of the cable and the cable sheath, connect the E terminal post to the cable sheath, the L terminal post to the core, and the G terminal post to the insulation layer between the cable sheath and the core, as shown in the image c.

The ammeter is connected in series with the circuit being measured to measure its current value. Depending on the nature of the current measured, it can be classified into DC ammeters, AC ammeters, and dual-purpose ammeters. Based on measurement range, there are microammeters, milli-ammeters, and ammeters. Based on the operating principle, they can be divided into electromagnetic, electrodynamic, and other types.

Portable clamp ammeter

1. Selection of Ammeter

For measuring DC current, the most commonly used is the electromagnetic type, but the electrodynamic or electromechanical types can also be used. For measuring AC current, the electromagnetic type is mostly used, while the electrodynamic type can also be used. In cases where high measurement accuracy and sensitivity are required, the electromagnetic type should be used; for less strict accuracy requirements and larger measurements, the electromagnetic type is often chosen for its lower price and higher overload capacity.

The range selection of the ammeter should be based on the size of the current being measured, ensuring that the measured current value falls within the ammeter’s range. When the size of the measured current is unclear, a larger range ammeter should be used for initial testing to avoid damage from overload.

The voltmeter is connected in parallel with the circuit being measured to measure the voltage value of the circuit. Based on the nature of the voltage measured, it can be classified into DC voltmeters, AC voltmeters, and dual-purpose voltmeters. Based on measurement range, there are millivolt meters and volt meters. Based on the operating principle, they can be divided into electromagnetic, electrodynamic, and other types.

1. Selection of Voltmeter

The principles and methods for selecting a voltmeter are similar to those for selecting an ammeter, mainly considering the measurement object, measurement range, required accuracy, and instrument price. For cases where accuracy is not critical, electromagnetic voltmeters are commonly used. For high accuracy and sensitivity requirements, multi-range electromagnetic voltmeters are usually adopted, with the voltage range of a multimeter being commonly used.

2. Usage Method

(1) Always connect the voltmeter in parallel with the two terminals of the circuit being measured.

(2) The voltage range of the voltmeter should be greater than the voltage of the circuit being measured to avoid damaging the voltmeter.

(3) When using an electromagnetic voltmeter to measure DC voltage, pay attention to the polarity markings on the voltmeter’s terminals, “+” and “-“.

(4) The voltmeter has internal resistance; the higher the internal resistance, the closer the measurement result is to the actual value. To improve measurement accuracy, a voltmeter with high internal resistance should be used whenever possible.

(5) When measuring high voltage, use a voltage transformer. The primary coil of the voltage transformer is connected to the circuit being measured, and the secondary coil has a rated voltage of 100 volts, connecting to a voltmeter with a range of 100 volts. The indicated value on the voltmeter multiplied by the transformation ratio of the voltage transformer gives the actual voltage value. The voltage transformer must be protected against short circuits in the secondary coil, usually by installing a fuse.

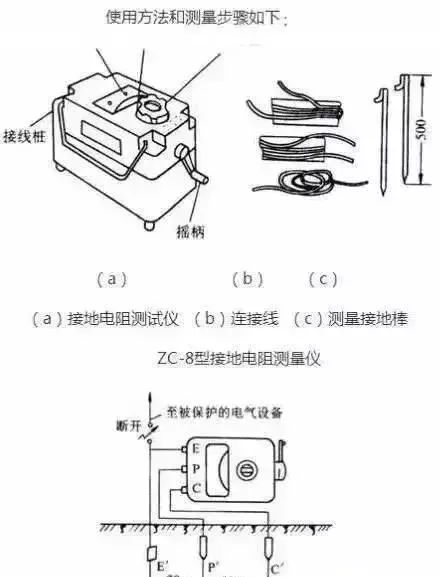

Ground resistance refers to the resistance of the grounding body buried underground and the soil’s leakage resistance.

Usage Method:

1. Disconnect the connection point between the grounding conductor and the grounding body, or disconnect all connection points of the grounding branches on the grounding conductor.

2. Insert two grounding rods into the ground 400mm deep, one 40m away from the grounding body and the other 20m away.

3. Place the shake meter on a flat area near the grounding body, then proceed with the wiring.

(1) Connect one wire from terminal E of the meter to the grounding body E′.

(2) Connect one wire from terminal C of the meter to the grounding rod C′ that is 40m away from the grounding body.

(3) Connect one wire from terminal P of the meter to the grounding rod P′ that is 20m away from the grounding body.

4. Adjust the coarse adjustment knob according to the required ground resistance of the grounding body (there are three adjustable ranges).

5. Shake the meter evenly at a speed of about 120 revolutions per minute. When the pointer deflects, adjust the fine-tuning dial until the pointer is centered. The reading after fine-tuning multiplied by the coarse adjustment resistance factor gives the ground resistance of the measured grounding body. For example, if the fine-tuning reading is 0.6 and the coarse adjustment resistance factor is 10, then the measured ground resistance is 6Ω.

6. To ensure the reliability of the measured ground resistance value, change the position and retest. Take the average of several measured values as the ground resistance of the grounding body.

(Source: Internet, copyright belongs to the original author)