What Is Pasteurization, and How Does It Keep Milk Safe?

Recent reports that the H5N1 avian flu virus has been found in cow’s milk have raised questions about whether the U.S. milk supply is safe to drink. According to the Federal Food and Drug Administration, the answer is yes, as long as the milk is pasteurized.

Recent reports have indicated that the H5N1 avian flu virus was detected in raw milk, raising concerns about the safety of the milk supply in the United States. The U.S. Food and Drug Administration (FDA) states that as long as the milk is pasteurized, it is safe to drink.

Nonetheless, raw (unpasteurized) milk sales are up, despite health experts’ warning that raw milk could contain high levels of the virus, along with many other pathogens. As an extension food scientist in a state where raw milk sales are legal, I provide technical support to help processors produce high-quality, safe dairy foods. I also like to help people understand the confusing world of pasteurization methods on their milk labels, and why experts strongly discourage consuming raw milk and products made from it.

Despite health experts warning that raw milk may contain high levels of the virus and other pathogens, sales of raw milk are increasing. As a food science extension agent in a state where raw milk sales are legal, I provide technical support to help dairy processors produce safe, high-quality dairy products. Additionally, I strive to help the public understand the confusing pasteurization methods listed on milk labels and explain why experts strongly advise against consuming raw milk and its products.

Dairy products, like many foods, have inherent risks that can cause a variety of illnesses and even death. Our milk comes from animals that graze outdoors and live in barns. Milk is picked up from the farm in tanker trucks and delivered to the processing plant. These environments offer numerous opportunities for contamination by pathogens that cause illness and organisms that make food spoil.

Dairy products, like many foods, carry inherent risks that can lead to various illnesses and even death. Our milk is sourced from cows that graze outdoors and are housed in barns. The milk is collected from the farm using tanker trucks and transported to processing plants. These processes present numerous opportunities for contamination by pathogens that can cause illness and microorganisms that lead to food spoilage.

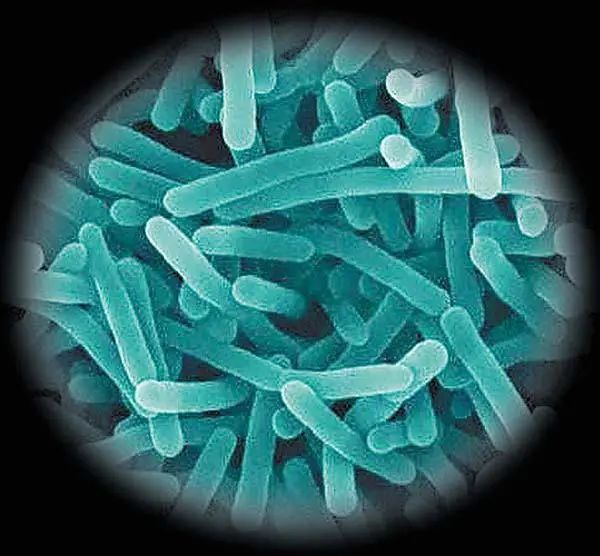

For example, listeria monocytogenes comes from environmental sources like soil and water. Mild infections with listeriosis cause flu-like symptoms. More serious cases are, unfortunately, too common and can cause miscarriages in pregnant women and even death in extreme cases.

For instance, listeria monocytogenes originates from environmental sources such as soil and water. Mild infections can lead to listeriosis, which presents flu-like symptoms. Unfortunately, more severe cases are not uncommon and can result in miscarriages among pregnant women and even death in extreme situations.

Other pathogens commonly associated with dairy animals and raw milk include E. coli, which can cause severe gastrointestinal infections and may lead to kidney damage; Campylobacter, the most common cause of diarrheal illness in the U.S.; and Salmonella, which causes abdominal pain, diarrhoea and other symptoms.

Other pathogens frequently linked to dairy animals and raw milk include E. coli, which can cause severe gastrointestinal infections and potentially lead to kidney damage; Campylobacter, the leading cause of diarrheal illness in the U.S.; and Salmonella, which results in abdominal pain, diarrhea, and other symptoms.

In the 1860s, French microbiologist Louis Pasteur discovered that heating wine and beer killed the organisms that caused spoilage, which then was a significant problem in France. This heating process, which became known as pasteurization, was adopted in the U.S. prior to World War II, at a time when milk was responsible for 25% of all U.S. outbreaks of foodborne illnesses. In 1973, the federal government required that all milk sold across state lines in the U.S. had to be pasteurized, and in 1987, it banned interstate sales of raw milk.

In the 1860s, French microbiologist Louis Pasteur discovered that heating wine and beer could kill the microorganisms responsible for spoilage, which was a significant issue in France at the time. This heating process, later termed pasteurization, was introduced in the U.S. before World War II, during a period when milk accounted for 25% of all foodborne illness outbreaks in the country. In 1973, the federal government mandated that all milk sold across state lines in the U.S. must be pasteurized, and in 1987, it prohibited the interstate sale of raw milk.

Pasteurization heats every particle of food to a specific temperature for a continuous length of time in order to kill the most heat-resistant pathogen associated with that product. Different organisms have different responses to heat, so controlled scientific studies are required to determine what length of time at a given temperature will kill a specific organism.

Pasteurization involves heating every particle of food to a specific temperature for a set duration to eliminate the most heat-resistant pathogens associated with that product. Different microorganisms respond differently to heat, necessitating controlled scientific studies to ascertain the time required at a specific temperature to effectively kill a particular organism.

Since 1924, pasteurization in the U.S. has been guided by the Grade “A” Pasteurized Milk Ordinance, a federal guidance document that is updated every two years to reflect current science and has been adopted by all 50 states. Pasteurization equipment in the U.S. must meet stringent requirements that include sanitary design, safety controls and material standards.

Since 1924, pasteurization practices in the U.S. have been governed by the Grade “A” Pasteurized Milk Ordinance, a federal guideline that is revised every two years to incorporate the latest scientific findings and has been adopted by all 50 states. Pasteurization equipment in the U.S. must adhere to strict standards, including sanitary design, safety controls, and material specifications.

Dairy processors can choose among several different types of pasteurization. When executed properly, all of these methods produce the same result: pathogen-free milk. Processors may treat milk beyond minimum times or temperatures to provide an extra margin of safety, or to reduce bacteria that can cause milk to spoil, thus increasing the product’s shelf life.

Dairy processors have the option to select from various pasteurization methods. When performed correctly, all these methods yield the same outcome: pathogen-free milk. Processors may opt to treat milk for longer than the minimum required times or temperatures to ensure an additional safety margin or to decrease bacteria that can lead to spoilage, thereby extending the product’s shelf life.

Vat pasteurizers, also known as batch pasteurizers, often are used by smaller-scale processors who handle limited volumes. The milk is pumped into a temperature-controlled tank with a stirrer, heated to a minimum of 145 degrees Fahrenheit (63 Celsius) and held there continuously for 30 minutes. Then it is cooled and pumped out of the vat.

Vat pasteurizers, also referred to as batch pasteurizers, are commonly utilized by smaller-scale processors who manage limited volumes. The milk is pumped into a temperature-controlled vat equipped with a stirrer, heated to a minimum of 145°F (63°C), and maintained at that temperature for 30 minutes. It is then cooled and pumped out of the vat.

The detection of avian flu virus fragments in milk is a new challenge for the dairy industry. Scientists do not have a full picture of the risks to humans but are learning.

The detection of avian flu virus fragments in milk presents a new challenge for the dairy industry. Scientists do not yet have a complete understanding of the risks to humans but are actively researching.

Research so far has shown that virus particles end up in the milk of infected cows, but that pasteurization will inactivate the virus. However, the FDA is advising consumers not to drink raw milk because there is limited information about whether it may transmit avian flu. The agency also is urging producers not to manufacture or sell raw milk or raw milk products, including cheese, made with milk from cows showing symptoms of illness.

Current research indicates that virus particles can be present in the milk of infected cows, but pasteurization can inactivate the virus. Nevertheless, the FDA continues to advise consumers against drinking raw milk due to limited information regarding its potential to transmit avian flu. The agency is also urging producers not to produce or sell raw milk or raw milk products, including cheese, made from milk sourced from cows exhibiting symptoms of illness.

The most common method used for commercial milk is high-temperature short-time pasteurization, which can treat large volumes of milk. The milk is pumped through a series of thin plates at high speed to reach a minimum temperature of 161°F (71°C). Then it travels through a holding tube for 15 seconds, and the temperature is checked automatically for safety and cooled.

The most prevalent method employed for commercial milk is high-temperature short-time pasteurization (HTST), which is capable of processing large quantities of milk. The milk is pumped through a series of thin plates at high velocity to achieve a minimum temperature of 161°F (71°C). It then passes through a holding tube for 15 seconds, during which the temperature is automatically monitored for safety before being cooled.

The most complex and expensive systems are ultra-pasteurizers and ultra-high-temperature pasteurizers, which pasteurize milk in just a few seconds at temperatures above 285°F (140°C). This approach destroys many spoilage organisms, giving the milk a significantly longer shelf life than with other methods, although sometimes products made this way have more of a “cooked” flavour.

The most sophisticated and costly systems are ultra-pasteurizers and ultra-high-temperature (UHT) pasteurizers, which can pasteurize milk in just a few seconds at temperatures exceeding 285°F (140°C). This method effectively eliminates many spoilage organisms, resulting in a significantly extended shelf life compared to other methods, although products processed this way may sometimes exhibit a more “cooked” flavor.

Ultra-high-temperature products are processed in a sterile environment and packaged in sterile packaging, such as lined cartons and pouches. They can be shelf-stable for up to a year before they are opened. Ultra-high-temperature packaging makes taking milk to school for lunch safe for kids every day.

Ultra-high-temperature products are processed in a sterile environment and packaged in sterile containers, such as lined cartons and pouches. They can remain shelf-stable for up to a year before being opened. Ultra-high-temperature packaging ensures that children can safely take milk to school for lunch every day.

It’s never a good time to get a foodborne illness, and this is the beginning of ice cream season. At a time when avian flu is showing up in new species and scientists are still learning about how it is transmitted, I agree with the FDA that raw milk poses risks not worth taking.

There is never a good time to contract a foodborne illness, and with the onset of ice cream season, caution is especially warranted. As avian flu continues to emerge in new species and scientists are still uncovering its transmission pathways, I concur with the FDA that the risks associated with raw milk are not worth taking.

-Key Vocabulary-

contamination v. Pollution

inactivate v. Inactivate

sterile adj. Sterile

-Previous Issues-

Bilingual Science Story | Permanent Chemicals in Water

Bilingual Science Story | At Least Two Countries Have Lost All Their Glaciers

Bilingual Science Story | What Is Sickle Cell Disease?

Source | Scientific American:

What Is Pasteurization, and How Does It Keep Milk Safe?

Image Source | Bing

Translator | Xu Zhiyuan

Reviewer | Wang Chunyu

Re-reviewer | Li Xiaohui

Executive Editor | Xu Zhiyuan

Editorial Reviewer | Wang Chunyu