One of the four great inventions of our ancestors in China—the compass—is widely known. For modern sensor technology, it can be regarded as the predecessor of magnetic sensors.

In today’s electronic age, magnetic sensors have a wide range of applications in motors, power electronics technology, the automotive industry, industrial automation, robotics, office automation, household appliances, and various security systems.

Magnetic sensors are devices that convert changes in magnetic properties caused by external factors such as magnetic fields, current, stress, strain, temperature, and light into electrical signals, thereby detecting corresponding physical quantities. They are used to sense speed, movement, and direction, with applications in automotive, wireless and consumer electronics, military, energy, medical, and data processing.

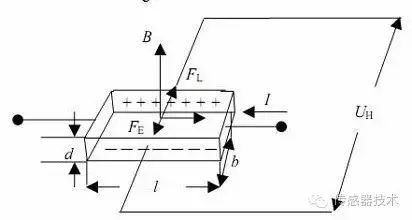

Diagram of the Hall Effect

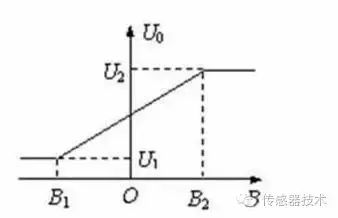

Working Principle of Linear Hall Sensors

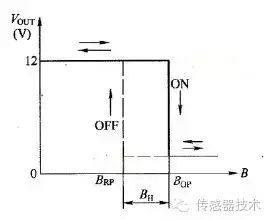

Working Principle of Switch Type Hall Sensors

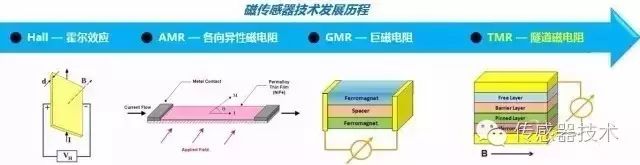

They use the potential difference generated by the Hall Effect to measure the magnitude and polarity of external magnetic fields. Magnetometers are planar devices using CMOS technology. The process is relatively simpler than that of general ICs, usually formed by a P-type substrate with N-well to create sensor devices, connected to other circuits (such as amplifiers, processing regulators, etc.) through metal electrodes.

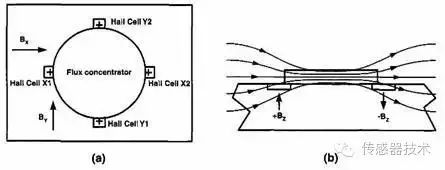

However, Hall sensors designed this way can only sense magnetic field changes perpendicular to the surface of the chip, thus a magnetic flux concentrator is added, which is essentially a layer of permalloy added to the original chip to detect magnetic fields parallel to the chip’s direction. This allows Hall sensors to achieve a leap from uniaxial to triaxial magnetometers.

Top View of Hall Sensor with Magnetic Flux Concentrator

Cross Section of Hall Sensor with Magnetic Flux Concentrator

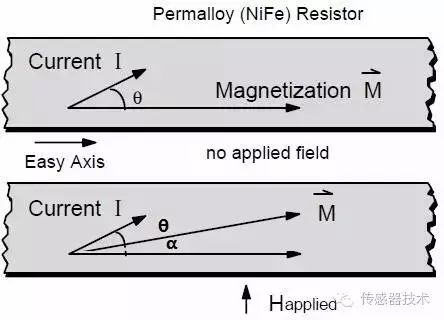

In 1857, Thomson discovered the anisotropic magnetoresistance effect of permalloy. For ferromagnetic metals with anisotropic characteristics, the change in magnetoresistance is related to the angle between the magnetic field and the current. Common examples of such metals include iron, cobalt, nickel, and their alloys.

When the external magnetic field is at zero degrees to the built-in magnetic field of the magnet, the resistance does not change with the external magnetic field; however, when there is a certain angle between the external magnetic field and the built-in magnetic field, the internal magnetization vector of the magnet will shift, reducing the film’s resistance. This characteristic is referred to as the anisotropic magnetoresistive effect (Anisotropic Magnetoresistive Sensor, abbreviated as AMR). The effect of the magnetic field is shown in the diagram below.

AMR Effect of Permalloy

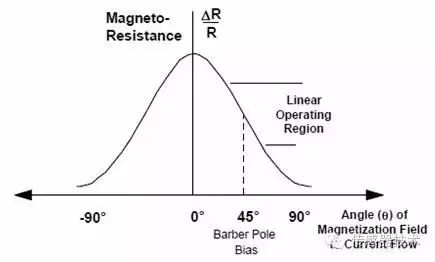

Relationship Between Magnetoresistance Change and Angle Change

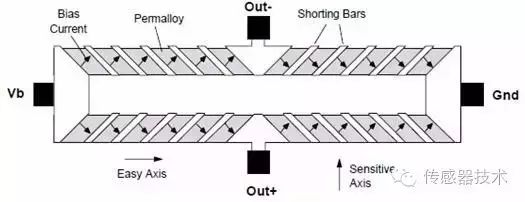

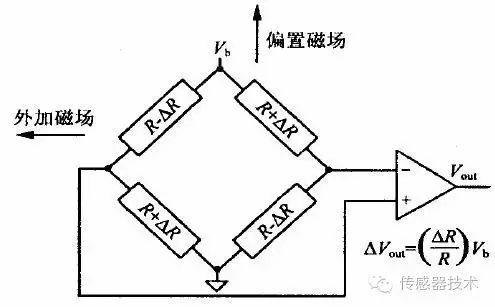

Equivalent Circuit of AMR Magnetic Sensors

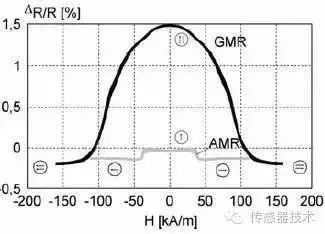

GMR and AMR Resistivity Changes Under External Magnetic Field

The term “giant” to describe this type of magnetoresistance effect comes not only from its apparent characteristics but also from its formation mechanism being different. Conventional magnetoresistance arises from the direct action of the magnetic field on the motion of electrons, presenting anisotropic magnetoresistance, which is related to the relative orientation of magnetization strength and current. In contrast, GMR magnetoresistance is isotropic and is fundamentally unrelated to the relative orientation of magnetization strength and current.

The Giant Magnetoresistance effect depends solely on the relative orientation of the magnetic moments of adjacent magnetic layers; the external magnetic field merely serves to alter the relative orientation of the magnetic moments of adjacent ferromagnetic layers. Furthermore, the GMR effect has significant implications for further exploration of new physics—such as tunneling magnetoresistance effect (TMR: Tunneling Magnetoresistance), spintronics, and new sensor technologies.

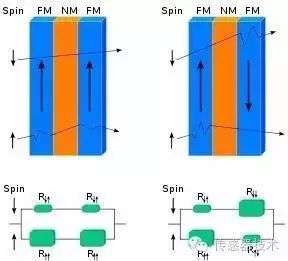

Basic Structure of Spin Valve GMR Sensors

Equivalent Circuit Diagrams Under Parallel and Anti-Parallel Magnetic Fields

As early as 1975, Julliere observed the TMR (Tunnel Magneto-Resistance) effect in Co/Ge/Fe magnetic tunnel junctions (MTJs). However, this discovery did not attract much attention at the time. In the subsequent decades, research progress on the TMR effect was slow. It was not until in-depth studies of the GMR effect that the TMR effect, also part of spintronics, began to gain attention. In 2000, the discovery of MgO as a tunnel insulator provided an opportunity for the development of TMR magnetic sensors.

In 2001, Butler and Mathon made theoretical predictions that using iron as the ferromagnetic material and MgO as the insulator, the tunneling magnetoresistance could reach several percent. In the same year, Bowen et al. first experimentally demonstrated the TMR effect in magnetic tunnel junctions (Fe/MgO/FeCo). In 2008, the team of S. Ikeda and H. Ohno from Tohoku University found that the resistivity change in the magnetic tunnel junction CoFeB/MgO/CoFeB reached 604% at room temperature and exceeded 1100% at 4.2K. The TMR effect’s significant resistivity change has led to increased interest in its research and product development.

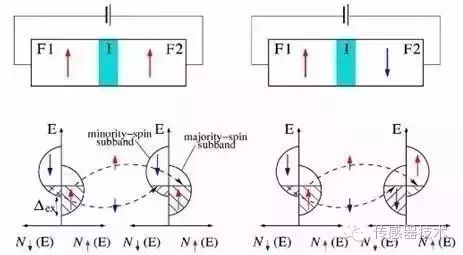

From the perspective of classical physics, the sandwich structure of ferromagnetic layer (F1) + insulating layer (I) + ferromagnetic layer (F2) cannot achieve electron tunneling through the magnetic layers, but quantum mechanics perfectly explains this phenomenon. When the magnetization directions of the two ferromagnetic layers are parallel, most electrons of the majority spin band can enter the empty states of the majority spin band in the other magnetic layer, while some electrons of the minority spin band can also enter the empty states of the minority spin band in the other magnetic layer, resulting in a larger overall tunneling current, putting the device in a low-resistance state;

When the magnetization directions of the two magnetic layers are anti-parallel, the situation is reversed: most electrons of the majority spin band will enter the empty states of the minority spin band in the other magnetic layer, while some electrons of the minority spin band will enter the empty states of the majority spin band in the other magnetic layer, leading to a smaller tunneling current, putting the device in a high-resistance state.

It can be seen that the tunneling current and tunneling resistance depend on the relative orientation of the magnetization strengths of the two ferromagnetic layers; when the magnetization direction changes, the tunneling resistance changes, hence the term tunneling magnetoresistance effect.

TMR Dual Current Model Under Parallel and Anti-Parallel Magnetization Directions

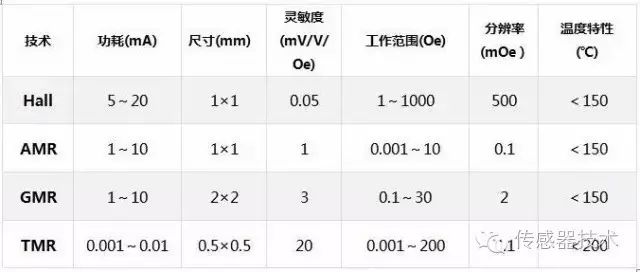

Comparison of Technical Parameters of Hall Devices, AMR Devices, GMR Devices, and TMR Devices

The application of magnetic sensors is very broad, playing an important role in the national economy, national defense construction, science and technology, and medical health, becoming a major branch of modern sensor industry. They are increasingly important in traditional industry applications and transformations, resource exploration and comprehensive utilization, environmental protection, bioengineering, and intelligent traffic control.

Source: Sensor Technology

END

Hot Articles (Scroll Up to Read)

Article Recommendation | Li Shuhua: Research on Online Monitoring Technology in Bearing Fault Diagnosis

Article Recommendation | Zhuoli: Pedestrian Multi-Attribute Collaborative Recognition Method Based on ResNet50 and Channel Attention Mechanism

Article Recommendation | Liang Minjian: Research on Mechanical Fault Classification of Escalators Based on One-Dimensional Convolutional Neural Networks

Article Recommendation | Hou Qilin: Prediction of Remaining Useful Life of Aviation Lithium Batteries Based on Indirect Health Indicators and Echo State Networks

Article Recommendation | Chen Peng: An End-to-End Natural Scene Text Detection and Recognition Model

Article Recommendation | Hou Feng: Remote Sensing Image Retrieval Based on Deep Feature Dictionary Learning and Largevis

Article Recommendation | Wang Xinyao: Global Inertial Navigation and Combined Navigation Method Based on Earth Coordinate System

Article Recommendation | Chen Lijing: Fault Diagnosis of Aviation Inverters Based on Multi-Class SVM

Article Recommendation | Li Mingfei: Discussion on Leaf Grid Shadow Experiment Image Enhancement and Flow Field Density Processing

Article Recommendation | Liu Qiuyu: Flexible Pressure Sensors Based on Capacitive-Resistive Conversion Principles

Article Recommendation | Li Lei: Research on Data-Driven Fault Prediction Methods

Article Recommendation | Yan Junjie: Automatic Precision Assembly Technology of Satellite Antenna Modules Based on Machine Vision

Article Recommendation | Yao Yanling: Research on Aviation Engine Surge Diagnosis Model Based on CNN-Seq2Seq

Article Recommendation | Guan Li: Overview of Electric Static Liquid Actuation Technology in Aircraft Flight Control Systems

Article Recommendation | He Yunze: Analysis of Acoustic Emission Signals of Power Devices in Inverter Circuits

Article Recommendation | Xie Li: Circuit Board Component Defect Detection Based on Improved YOLOv4 Network

Article Recommendation | Wang Yizhou: Short Video Fingerprint Extraction Based on R(2+1)D Twin Network

Article Recommendation | Han Han: Overview of No-Reference Image Quality Assessment Based on Deep Learning

Article Recommendation | Wang Jiulong: Research on Fatigue Test Technology of Helicopter Tail Rotor Blades

Article Recommendation | Sun Weihong: Research on Portable ECG Monitoring System Based on Flexible Electrodes

Article Recommendation | Zhang Meiju: Research Status and Development Trends of Ceramic Substrate Thin Film Thermocouples

Article Recommendation | Ouyang Lin: Fatigue Driving Detection Algorithm Based on Driver Facial Temporal Data

Article Recommendation | Zhang Wenli: Multi-Target Tracking Algorithm Based on Improved Transformer with Anchor-Free Network

Article Recommendation | Liu Guanjun: Research Progress of Silicon-Based and Graphene-Based Resonant Pressure Sensors

Article Recommendation | Jiang Chao: Overview of Image-Based Drone Battlefield Situation Awareness Technology

Article Recommendation | Zhang Feiyang: Overview of Alertness Detection Research Based on Physiological Signals

Article Recommendation | Qiu Fang: Research on Autonomous Management Software Architecture for Deep Space Exploration Spacecraft Control Systems

Article Recommendation | Wang Yanshan: Research on Testing Technology System Architecture for Civil Aircraft

Article Recommendation | Liu Yawei: Research on Digital Twins for Aircraft Structural Health Management

Article Recommendation | Sun Zhiyan: Overview of the Development of Aviation Engine Control Systems

Forum Discussions | Academician Gao Jinjie: Intelligent Monitoring of Vibration Faults in Aviation Engines

Forum Discussions | Wang Haifeng: Discussion on the Intelligent Development of Aviation Equipment Support

Forum Discussions | Wang Huamao: Overview of Comprehensive Testing Technologies and Development Trends for Spacecraft

Forum Discussions | Li Kaisheng: Discussion on Testing and Control Technology Requirements for Large Aircraft Power Systems

2021 Excellent Papers Collection in Computer and Automation Technology

2021 Excellent Papers Collection in Aerospace

2020 Excellent Papers Collection in Aerospace

2020 Excellent Papers Collection in Computer and Automation Technology

Journal Updates (Scroll Up to Read)

Notice of Call for Papers for the “Gas Turbine Engine Measurement and Control Technology” Column in Measurement and Control Technology

Journal Directory (Scroll Up to Read)

2022 Issue 12

2022 Issue 11

2022 Issue 10 Special Issue on Intelligent Testing Technology for Onboard Systems

2022 Issue 9 Special Issue on Advanced Sensors and Atmospheric/Meteorological Measurement Technologies

2022 Issue 8

2022 Issue 7

2022 Issue 6

2022 Issue 5

2022 Issue 4

2022 Issue 3

2022 Issue 2

2022 Issue 1

2021 Issue 12

2021 Issue 11 Special Issue on Status Monitoring Sensor Technologies

2021 Issue 10

2021 Issue 9

2021 Issue 8

2021 Issue 7

2021 Issue 6

2021 Issue 5

2021 Issue 4

2021 Issue 3

2021 Issue 2

2021 Issue 1

2020 Issue 8 Special Issue on Machine Vision Technology

2020 Issue 12 Special Issue on Artificial Intelligence and Testing Support