Recommended Reading: Meeting Notice丨Letter on the 17th Smart City Conference

Conference Announcement:

We welcome submissions from all relevant units for the selection of excellent cases

Submission Email: [email protected]

Contact Number: 010-68716602

★Case Submission Display★

Qingdao Energy Group Integrated IoT Management Platform

Duan Xubao, Zhao Peng, Liu Lu

Qingdao Energy Group Co., Ltd.

Haina Cloud IoT Technology Co., Ltd.

1. Background of Construction

In recent years, urban gas has achieved tremendous development, but due to various challenges involving urban safety, public service satisfaction, enterprise profitability, and regional energy supply-demand balance, gas companies have faced many management difficulties in their operations.

1. Meter Reading Difficulties, Charging Difficulties, Payment Difficulties

The business operation model of urban gas companies relies on pipeline networks to deliver products, using meters for measurement and trade settlement to complete gas supply, sales, and services. The accuracy, frequency of meter readings, and timely payment by users directly affect the company’s efficiency and cash flow rate.

Due to the inefficiency of traditional manual meter reading, backend billing systems often require centralized billing at the end of the month, and paper bills are sent to customers, who must then visit designated service centers to pay, which is time-consuming and labor-intensive.

Currently, Qingdao Energy Group has over 20 data collection systems, with different business data scattered across various systems. Currently, each enterprise operates its multiple business systems independently, requiring ongoing data comparison for new users, leading to repetitive labor, a high workload, and a high error rate, which is detrimental to subsequent service work and hinders the collaborative value of data.

2. Safety in Gas Supply and Usage

For public utility companies, poor supply and distribution of gas, along with leakage, are significant threats to company profitability. Physical leaks in pipelines, measurement errors in meters, and the inability to monitor user gas theft behavior in a timely and effective manner lead to substantial losses for gas companies.

Gas pipelines also concern safety; corrosion, gas leaks, excessive pressure, high temperatures, and unsafe user behavior must be monitored in real-time to prevent and eliminate dangers.

Therefore, gas companies urgently need technological means to enhance real-time monitoring of pipeline temperature and pressure, monitor user gas behavior, and issue alarms for terminal anomalies or perform remote valve control.

3. Tiered Pricing and Energy Conservation

To promote the healthy development of the natural gas industry, fully utilize price levers to adjust regional supply-demand balance, and guide users in energy conservation and emission reduction, natural gas price reforms have deepened in recent years, with non-residential gas prices being increasingly liberalized and tiered pricing for residential gas already implemented in many areas nationwide. The complexity of billing and frequent price adjustments require precise measurement, making traditional management models no longer applicable.

4. Internet + Gas Innovative Services

The applications of IoT, mobile internet, and big data have raised higher demands for the management and services of energy companies. Some urban gas companies have begun exploring Internet + gas innovative services, actively utilizing channels such as WeChat, Alipay, and corporate apps for payments, tapping into vast user resources, and developing gas insurance and value-added sales of gas appliances; in terms of safe operations, some companies have started researching and applying predictive maintenance algorithms for gas pressure regulation equipment and heat exchange station equipment based on real-time data from IoT platforms, injecting new vitality into gas heating enterprises under the new economy.

With the development of IoT technology, there is an urgent need for an IoT platform to integrate and access production, operation, and business data to support the application of smart gas.

2. Construction Content

1. Construction of Smart Energy IoT Platform

Following the principle of “Everything Connected, Real-Time Perception,” the platform integrates the fields of gas and heating, connecting massive monitoring IoT devices including gas meters (for residential and commercial users), pipelines, gas stations, heat exchange stations, and heat sources to the IoT platform, with real-time data uploaded to the platform. The platform also has functions for device management, data management, and integration and analysis with existing systems, allowing device data to flow flexibly to other services or message middleware, ensuring comprehensive operation of IoT business, providing data integration and aggregation work, supporting data analysis, judgment, and decision-making data. Through IoT, big data, modeling simulation, artificial intelligence, GIS, and other technical means, a digital twin model that maps the entire process of the actual physical energy system from “source-network-station-user” will ultimately be constructed, forming a panoramic view of group operations, achieving precise control of operational services. This will create a benchmark product in the smart energy field and establish a rich model library for energy terminal products, while empowering the IoT device access and management capabilities for the entire energy industry SaaS platform.

2. Overall System Architecture

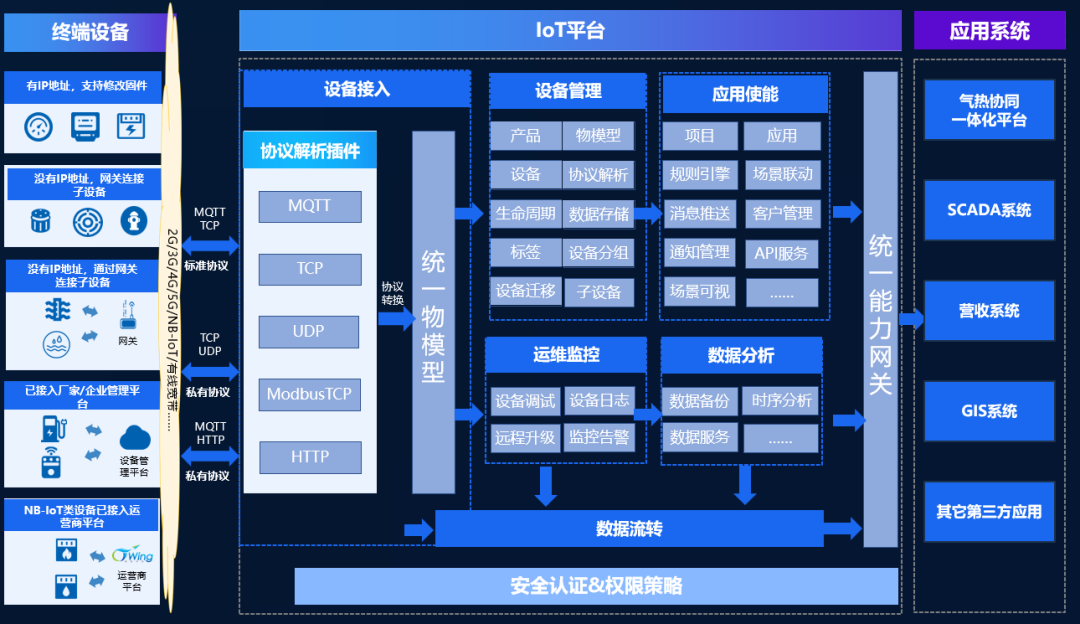

The smart energy IoT platform supports cloud-edge hybrid capabilities and mainly consists of four layers: AIoT platform, network layer, perception layer, and data forwarding layer, providing an overall technical solution for interactions between terminal energy devices and upper-level SaaS applications. As shown in Figure 1.

Figure 1 Overall System Architecture

2.1 AIoT Platform Layer

The AIoT platform provides services such as device access, authentication, message parsing and storage, and device control to the south, and offers device management services and Open API services to external third-party systems through microservice clusters and self-built IoT gateways to the north. The platform also provides a web portal for customers to create and manage products and devices; furthermore, the platform can forward data to third-party applications or message queues through a rules engine;

2.2 Network Layer

Directly connected devices and gateway sub-devices can connect to the platform through various protocols such as MQTT, HTTP, CoAP, LwM2M, and various communication methods such as 3G/4G/5G, NB-IoT. It supports near-field communication networks such as WiFi, Bluetooth, Zigbee, NFC, OPC, and Modbus.

2.3 Perception Layer

This includes various types of energy terminal devices such as directly connected devices, gateway devices, and gateway sub-devices. Directly connected devices and gateway devices can connect directly to the platform; gateway sub-devices connect with gateway devices, achieving data exchange with the platform. This encompasses a variety of energy terminal devices from heat sources, heat exchange stations, and cathodic protection of heating networks, realizing data interaction between energy devices and upper-level applications.

2.4 Data Forwarding Layer

The IoT perception cloud platform provides data forwarding and rules engine functions based on Kafka message queue pushing, pushing device-related attribute data and alarm event information to the north-facing SaaS management platform via API interfaces, achieving real-time alarms, real-time data transmission, and real-time device management business logic functions.

3. Main Functions of the System

The platform is based on the access of IoT perception terminals of the energy group, covering gas meters, heat meters, IoT cathodic protection, and other IoT perception devices, realizing data aggregation of multi-brand IoT perception data, and specifically establishing independent partition libraries for various scenario devices to manage IoT perception device data. After data aggregation, it can simultaneously transfer to various third-party application platforms, constructing a unified service system for IoT perception devices and data, supporting the rapid establishment of various business scenarios for the energy group. As shown in Figure 2.

Figure 2 Qingdao Energy IoT Platform

Perception device access management: For sensor-type IoT perception devices, they can be directly connected to the IoT perception platform through various manufacturer interface protocols. In this project, various specialized devices support 4G dedicated lines, NB-IoT, and IoT perception dedicated line network connections, quickly connecting to the platform through MQTT, TCP, HTTP, and other data protocols.

Data services: After the IoT perception platform accesses various perception devices’ basic data and alarm data, it transmits the data to the data middle platform and various third-party application systems according to the platform’s access standards and interface specifications via a unified API interface.

3.1 Perception Device Access

All devices in this project can be accessed through 4G dedicated lines, NB-IoT wireless cellular networks, and IoT perception dedicated line access, supporting access via MQTT and HTTP industry standard protocols. It provides an end-to-end secure access authentication mechanism, supporting authentication of devices accessing the platform and receiving data reported by devices. The authentication method supports one model one key, meaning each model of device has a unique authentication parameter, ensuring that all devices accessing the platform are authorized, avoiding illegal devices connecting to the platform.

1) Standard Protocol Access

Currently, the construction of the IoT perception platform faces issues such as long construction cycles, repeated constructions, poor interoperability, and high complexity in the development process of IoT application systems. To address these issues, the IoT perception platform establishes a standardized architectural system to shield underlying object differences, presenting a unified service calling interface for IoT applications, facilitating rapid construction of IoT applications, ensuring interoperability and operability among systems.

2) Message Protocol Management

For the private protocol devices from various IoT device manufacturers in this project, the platform provides data parsing functionality, supporting custom data format (binary) conversion between self-defined protocol packets and standard object model data formats.

3) Network Component Management

Network component management is the information packaging and usage permission configuration section for platform-defined protocol plugins, allowing for configuration of information for custom protocol plugins.

4) Protocol Plugin and Product Matching

After completing the development of docking protocol plugins, the protocol must be matched one-to-one with the product and complete the relevant configuration, preparing for data connectivity between the platform and device platform. By completing the configuration of platform, product, and docking instructions in the pop-up window, the matching of products and protocol plugins is completed.

3.2 Perception Device Management

1) Product Management

Products support staff from the energy group to actively create according to device characteristics, with permissions for product information usage/viewing, object models, topics, product metadata, device metadata definitions, and subscription management.

2) Dynamic Device Management

The system can provide basic dynamic management functions for devices, supporting adding, editing, deleting, querying, status monitoring, batch importing, enabling/disabling, viewing device information, object models, service calls, and device metadata.

3) Device Grouping

The platform provides device grouping functionality to achieve custom device resource combinations and grouping permission control within a single project. In grouping management, groups can be created by entering group names and descriptions.

4) Object Model Management

The object model is a digital abstract description language for devices and is the core of accessing perception devices. It describes what the model of the device is, what perception data it provides, and what services it can offer externally. The object model digitizes physical entities in space and constructs the data model of the entity on the platform, helping users standardize the data model of perception devices and facilitating more convenient device data management.

5) Sub-device Management

The platform provides sub-device management functions under communication devices, supporting the access of gateway devices and managing the parent-child relationship between gateways and sub-devices. Users can associate and unbind sub-devices on the device topology management page and synchronize the topology relationship to gateway sub-devices.

6) Device Migration

The platform supports the migration of devices under existing products to other accounts, changing the account relationship associated with the devices. It supports device migration at the product level, allowing configuration of target accounts, selected products, and migration instructions in the migration pop-up window to complete the operation.

3.3 Perception Data Distribution

The IoT perception platform provides data distribution capabilities after collecting sensor data from the energy group, supporting HTTP and MQTT push methods. HTTP push has a simple docking process and requires less development work; MQTT push uses MQTT message middleware, which is highly universal and adaptable, supporting multiple application subsystems’ data integration needs simultaneously; the two methods combined can meet diverse message push requirements.

1) Rules Engine

The rules engine provides the core service for users to transfer data flows; users can define rules to filter and select all relevant data from platform devices, forwarding the data to the platform communication components, facilitating upper-level application development. The rules engine can be divided into three modules: message source, message processing, and message distribution.

2) Scene Interaction

Device scene interaction supports the configuration of rules to trigger interactions between different devices within the platform.

3) Notification Management

Through notification configuration creation, corresponding notification templates match and associate rules engine, achieving the platform’s function of pushing device data in forms like emails to the maintained network.

4) Alarm Center

The platform supports forwarding alarm notification services from data pushed by the rules engine, allowing for pre-setting related device uplink trigger data push rules, enabling timely reception of alarm information after rule triggers.

3. Innovative Applications

The construction of this IoT platform and the comprehensive integration and upgrading of operational data will assist the group in creating an energy information network, standardizing data standards, unifying technical routes, injecting intelligent power, deepening system applications, continuously improving the company’s operational management level, enhancing customer service experience, and achieving uniform, high-quality services for gas and heating across the city. The core applications and innovative highlights of the platform are as follows:

1. Core Applications

Universal protocol plugin parsing: The platform standardizes all perception data across the board, based on IoT object model standards, addressing pain points such as inconsistent data standards, device incompatibility, and non-interoperable applications among similar IoT devices from different manufacturers, achieving unified standards for perception data and plug-and-play device applications for over 30 types of IoT devices used by customers.

Multi-tenant exclusive experience: ① Based on a multi-tenant data isolation architecture and permission control system, the open platform provides unified device access and data sharing, decoupling devices from business applications and flexibly deriving scene-based applications; ② Under the permissions of their respective accounts, users can freely define products through the “object model,” achieving self-service for “creating products – device debugging – data governance – application development” on a visual interface. The platform’s openness resolves the previous issue of needing a dedicated device platform for each IoT device used. The platform supports multi-tenant applications, as many secondary and tertiary subsidiaries of the energy group operate independently, making the platform’s openness and flexible permission management functions highly supportive.

Multi-device scene interaction: Automated collaboration across various device types: By configuring scene interaction rules, when project data meets preset conditions, the system automatically executes predefined business logic to control device interactions. To facilitate efficient docking of third-party application systems with the IoT platform to retrieve uplink data and downlink control, the platform offers various operational and data interaction methods.

Time-series database: Through innovative storage design, adopting lock-free design and multi-core technology, the speed of data insertion and querying exceeds existing professional time-series databases by more than ten times.

Microservice architecture: Fully considering future customer demand upgrades and technological innovations, the system splits services into multiple process services according to business characteristics. As the number of device connections increases or the concurrent data reporting volume rises, services can be rapidly horizontally scaled. Despite the continuous expansion of the user scale of the energy group and the increasing number of IoT platform devices, with over 2 million IoT devices connected, the platform ensures horizontal scalability of system processing capabilities through advanced cluster design, eliminating reliance on expensive hardware and storage devices, and preventing any single point of bottleneck or failure.

2. Innovative Highlights

2.1 Helping Improve Enterprise Efficiency and Safe Operations

Gas and heating enterprises prioritize safe operations as their first goal, integrating and accessing data from various specialized business systems. Through data integration and analysis, they can monitor the operating status of on-site equipment, analyze operational patterns, and predict to avoid accidents, enhancing production safety and reliability.

2.2 Facilitating Information Resource Sharing

Through the platform’s construction, enterprises can aim to resolve the “information island” problem between internal application systems around information sharing and coordination work, avoiding redundant investments and laying the foundation for further system planning and implementation.

Promoting data analysis and mining: Unified data collection standards can provide a more comprehensive and accurate data source for data analysis and mining, helping discover the potential value and patterns of data, thus providing stronger support for enterprise decision-making.

Reducing data management costs: Unified data collection standards can lower the complexity and costs of data management, reduce data redundancy and duplication, and improve the efficiency and effectiveness of data management.

2.3 Establishing a Scientific Management Standard System

By constructing the IoT platform, a unified data collection standard, network access standard, and security encryption standard can be established, forming an enterprise-level management standard system. This brings the following advantages:

Improving data quality: Unified data collection standards can ensure the accuracy and consistency of data, reducing anomalies and redundancy, thus enhancing data quality.

Enhancing data security: By implementing unified data collection standards, more comprehensive data security strategies can be developed, including data encryption, backup, and recovery, thereby enhancing data security.

Improving data integrability: Unified data collection standards facilitate the integration of data from different sources, achieving centralized management and sharing of data, thus enhancing data integrability.

4. Promotion Value

This project established a group IoT platform, achieving the goal of “Everything Connected, Real Data; Convenient Querying, Quick Statistics; Accurate Analysis, Effective Control.” The IoT platform enables secure access for IoT terminals, completing functions such as protocol parsing, device management, data processing, storage and routing, alarm generation, etc., achieving two-way data transmission with mainstream client management platforms through the establishment of information standards and the standardized management of data resources. The group can collect data from bottom to top through the system, achieving real-time data collection and comprehensive centralized management, continuously improving the timeliness, completeness, and accuracy of perception data, providing data support for comprehensive query analysis and big data applications. The resulting social and economic benefits are as follows:

1. Social Benefits

Enhancing Public Safety: The IoT platform can monitor the operational status of gas and heating pipelines in real-time, promptly identifying and preventing potential safety hazards, ensuring the stability and safety of urban heating, reducing gas leakage incidents, and enhancing public safety.

Improving People’s Livelihood: Through IoT technology, gas and heating enterprises can more accurately control heating temperature and quality, improve heating efficiency, and provide citizens with a more comfortable living environment, enhancing welfare.

Promoting Green Development: The application of the IoT platform by gas and heating enterprises helps reduce energy consumption and emissions, promoting a green and low-carbon energy consumption model and sustainable urban development.

Enhancing Public Service Levels: By utilizing real-time data collected by the IoT platform and sharing it with revenue customer service systems, gas and heating enterprises can offer more intelligent and convenient services, such as online repair requests and intelligent customer service, enhancing public service levels and social satisfaction.

2. Economic Benefits

Reducing Operational Costs: IoT technology can help gas and heating enterprises achieve remote monitoring and maintenance, reducing the need for manual inspections and lowering operational costs. Additionally, through data analysis and optimization, equipment operational efficiency can be improved, further reducing costs.

Improving Production Efficiency: Through real-time monitoring and intelligent scheduling, the IoT platform can optimize the production and supply process of gas and heating, improving production efficiency and meeting market demands.

Expanding Business Fields: Leveraging innovative applications of IoT technology can support gas and heating enterprises in expanding into new business areas, such as smart gas safety alarm services and industrial heating, creating new growth points for enterprises.

Enhancing Market Competitiveness: By improving operational efficiency and providing high-quality services, the gas and heating enterprise IoT platform can help companies gain a competitive edge in the market.

3. Promotion Value

Driving Industrial Transformation and Upgrading: The construction of the IoT platform can help enterprises collect and accumulate daily operational data, laying the foundation for data asset accumulation, promoting the digital transformation and upgrading of the energy industry, transitioning from traditional energy to clean and smart energy.

Through the IoT platform, real-time monitoring, data analysis, and intelligent scheduling can optimize the production and supply process of gas and heating. This not only helps reduce energy consumption and emissions but also improves production efficiency to meet market demands. Additionally, leveraging the IoT platform, enterprises can expand into new business fields, such as smart home heating, industrial heating, and predictive maintenance of equipment, creating new growth points for enterprises.

The promotion and application of the IoT platform will lead gas and heating enterprises towards a path of digitalization and intelligence, driving industrial upgrading. Through unified data collection and sharing, enterprises can better understand customer needs and provide personalized services. Furthermore, with big data analysis, enterprises can optimize decision-making processes and enhance operational efficiency. This will bring stronger market competitiveness to enterprises, achieving sustainable development.

Leading Industry Innovation: The successful application of the Qingdao Energy Group gas and heating enterprise IoT platform has established the first unified IoT platform for gas and heating in the country, demonstrating a good model effect. Promoting the application of the gas and heating enterprise IoT platform can lead the entire industry to continuously innovate and explore new business models and fields.

4. Standardized Implementation Path of the IoT Platform

Demand Analysis: First, it is necessary to analyze the standardized requirements of the IoT platform, including industry needs, application needs, and technical needs. This requires a deep understanding of the application scenarios, technical bottlenecks, and industrial development trends of the IoT platform to determine the key directions and goals of standardization.

Standard Formulation: Based on the results of the demand analysis, standards for the IoT platform should be formulated. The content of the standards should include regulations on platform architecture, interface specifications, data exchange formats, security, and privacy protection. During the formulation of standards, issues such as compatibility, scalability, and interoperability should be fully considered.

Testing and Verification: After formulating the standards, testing and verification are needed. For the gas and heating industry, small-scale IoT gas meters or heat meters in selected communities can be tested to ensure the feasibility and effectiveness of the standards. Testing and verification can be conducted in simulated or real application environments to evaluate the functionalities and performance of the IoT platform.

Promotion and Application: Once the testing and verification are successful, the standards of the IoT platform need to be promoted and applied at the company or group level. This can be achieved through training, promotional activities, and technical support from headquarters to drive the standardized application and development of the IoT platform, ensuring comprehensive application at the company or group level.

Feedback Optimization: During the promotion and application process, it is essential to timely collect feedback information and continuously optimize and improve the standards. Additionally, it is crucial to pay attention to the technological development trends and application trends of the IoT platform, continuously updating and improving the standard content and upgrading the IoT platform with new technologies.

Conference Cooperation/Participation/Exhibition/Join Discussion Group

Recommended Reading

✩Construction of an Online Review System for Government Services for Engineering Archives

✩Tianjin Smart City Simulation and Deduction Model Platform

✩Urban Space Deduction Simulation System Oriented to Land and Space Planning Applications

✩Dongguan “Graph-Data Interaction for Land Supply” Application

✩Liangxi District Builds a New Smart City Operation Brain Model of “1+1+3”

✩Muping District Big Data Service Center Builds a Comprehensive Supervision System for Pine Wood Nematode

✩Muping District Builds an “Integrated Sensing System” for All-Dimensional Monitoring Management

✩Yima City Smart Elderly Care Service Platform Construction Project

✩Intelligent Applications Promote Digital Governance at the Grassroots Level

✩Qingzhen City Urban-Level Smart Parking Project Construction

✩Time-Space Big Data Cloud Platform, Building Muping Smart City Digital Foundation

✩Langfang Airport Economic Zone New Smart City Construction

✩Gulou District Smart Water Service Big Data Comprehensive Management Platform

✩Hanyang District Co-Building and Co-Evaluating Platform for a Beautiful Environment and a Happy Life

✩AI Large Model Solutions for Modern Grid Governance Scenarios

✩Smart Supervision Platform for Rail Transit Projects Based on 3D Digital Base

✩Empowering Urban Governance with Digital Twin Technology to Enhance the Comprehensive Environment of the Guangzhou Tower

✩Research and Application of Integrated Monitoring Methods for Inland River Channel Maintenance

✩Goldwind Technology Yizhuang Carbon Neutral Smart Park

✩Construction and Application of a Smart Platform for Full Lifecycle Management of Construction Projects Based on BIM

✩Haisai Prefecture Land and Space Planning Informationization Project

✩Exploring Smart Governance Paths in Haizhu through “One Map Sensing All States, One Map Commanding Co-Governance”

✩Emergency Surveying and Mapping Linked Service Platform and Its Application Demonstration

✩Informationization Production and Management System for Whole Process Supervision

✩Empowering Urban Governance with Digital Twin Technology to Enhance the Comprehensive Environment of the Guangzhou Tower

✩Smart Community Operation Management Platform Based on Digital Twin

✩Shan Jian Installation Building Intelligent Application Project

✩Realistic Three-Dimensional Intelligent Visualization Analysis Platform for Land and Space Planning