The intelligent drilling technology integrates theories and technologies from geology, control engineering, mechanical mechanics, data analysis, intelligent algorithms, and data transmission. The core technologies mainly include Measurement While Drilling (MWD), Logging While Drilling (LWD), intelligent drilling rigs, intelligent drill bits, intelligent drill pipes, intelligent pressure control drilling technology, and remote intelligent drilling decision control systems.

1. Measurement While Drilling Technology

Downhole measurement while drilling technology mainly includes MWD, LWD, Pressure While Drilling (PWD), Acoustic Wave Logging While Drilling (AWD), Seismic While Drilling (SWD), Nuclear Magnetic Resonance Logging While Drilling (NMR-LWD), and Formation Evaluation While Drilling (FEWD).

The measurement while drilling technology can not only obtain real-time information about geological parameters, wellbore trajectory, and drilling engineering downhole, but also evaluate the drilled formations in real-time.

MWD can measure the inclination, azimuth, and other spatial position parameters of the drill bit in real-time, thus calculating the real-time deviation vector of the wellbore trajectory at any moment;

LWD can measure resistivity, neutron, density, and gamma parameters while drilling;

SWD uses the vibrations generated by the drill bit during drilling as a downhole seismic source, which can determine the spatial position of the drill bit, the lithology of the formation near the drill bit, and the presence of oil and gas.

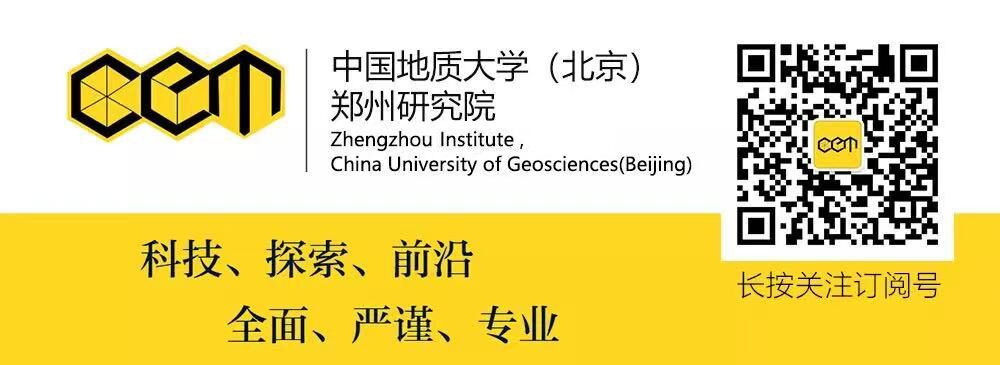

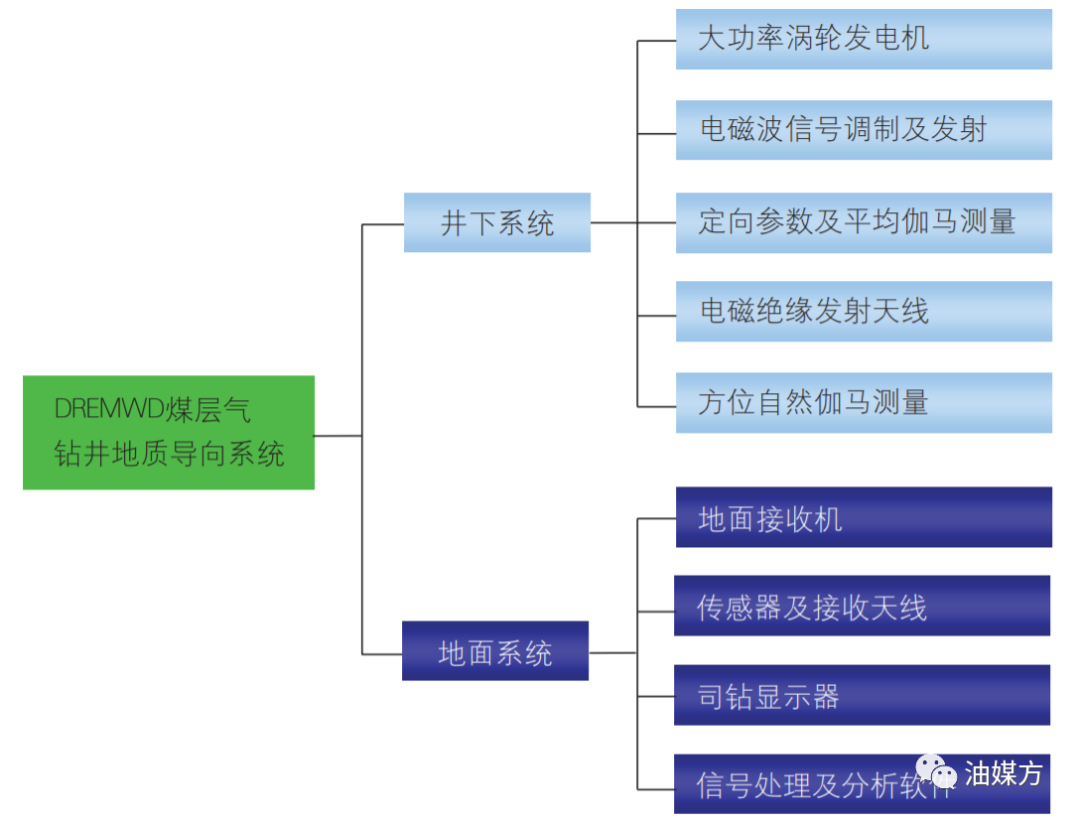

Figure 1: Components of DREMWD Measurement System

The DREMWD measurement system developed by China National Petroleum Corporation can achieve a maximum transmission rate of 11 bit/s and a maximum working pressure of 100 MPa; Beijing Blue Ocean Technology Company has developed a mud pulse measurement system with high anti-vibration capability, compact structure, suitable for small borehole drilling.

The measurement while drilling technology will develop towards detecting more, more accurately, further, and faster.

2. Intelligent Steering Drilling Technology

The intelligent steering drilling system is equipped with highly functional adjustable downhole tools, which can intelligently optimize the drilling direction and wellbore trajectory using artificial intelligence algorithms based on downhole geological information and wellbore trajectory parameters obtained from measurement while drilling, automatically adjusting the drill bit nozzle direction, drilling mud flow rate, and flow, controlling the drill bit’s drilling direction, and timely adjusting the relationship between the wellbore trajectory and the production layer’s position to ensure that the drill bit drills around the target oil and gas layer.

(1) Schlumberger’s third-generation Power Drive Archer system establishes an intelligent control algorithm for wellbore trajectory, capable of predicting side drilling positions and intelligently adjusting drilling parameters when the wellbore trajectory deviates, automatically correcting the wellbore trajectory.

(2) Based on continuous proportional control methods, Baker Hughes’ Auto-Trak Curve steering drilling system can improve the smoothness of the wellbore, achieving more precise target drilling.

(3) Halliburton’s iCruise intelligent steering drilling system is equipped with advanced sensors, communication devices, and powerful processors, capable of producing a well inclination angle of 18°/30m.

Figure 2: Halliburton iCruise Intelligent Rotary Steering System

(4) Based on the dual-loop feedback cooperative control principle, the China National Offshore Oil Corporation has developed the Welleader rotary steering drilling system, applied to the three-dimensional wellbore trajectory design control of experimental wells.

The intelligent steering drilling technology still has a distance to achieve large-scale commercialization and needs breakthroughs in high-performance intelligent processors and intelligent steering drilling tools.

3. Intelligent Drilling Rig

The intelligent drilling rig can achieve unmanned operations by monitoring downhole working conditions in real-time through the drilling control center, adjusting various working parameters of the drilling rig, and automatically completing multiple operational processes.

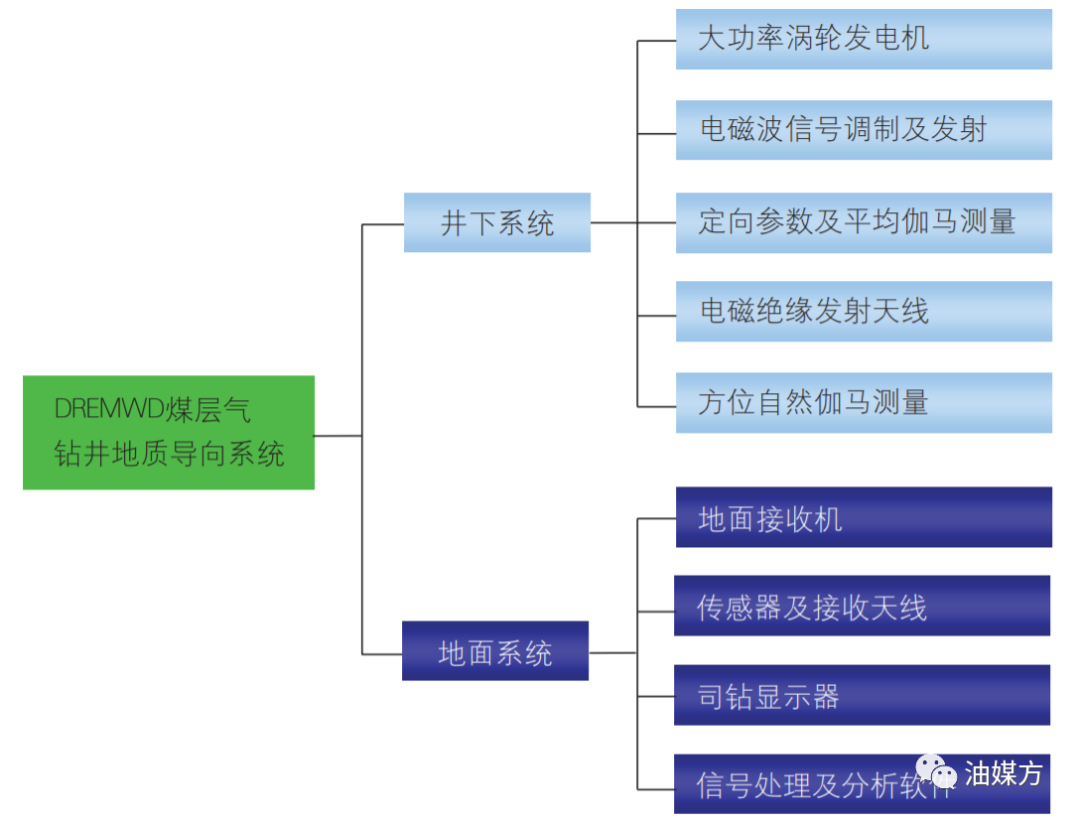

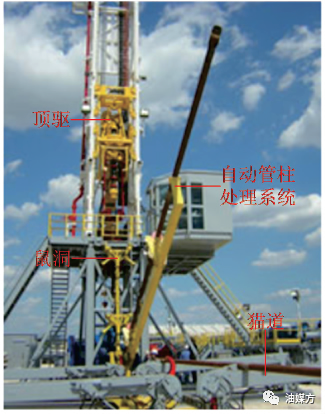

(1) The RAPID intelligent drilling rig developed by NOV in the United States can automatically install and replace drill pipes, requiring only one operator for the entire drilling platform, and can adapt to various complex drilling environments.

Figure 3: RAPID Intelligent Drilling Rig

(2) The T500XD intelligent drilling rig developed by Schramm in the United States features an integrated intelligent control room that does not require the involvement of drilling and derrick personnel, transmitting real-time downhole data to multiple locations for remote connection control via satellite or the Internet.

(3) The intelligent drilling rig developed by Norwegian RDS Drilling Company has self-learning, memory, and judgment capabilities, capable of using different tubular operation tools to perform drilling operations accurately and efficiently.

(4) The small intelligent drilling rig developed by Baoji Petroleum Machinery Co., Ltd. can achieve functions such as automatic pipe replacement and unmanned drilling control.

(5) The primary intelligent drilling rig designed by the Drilling Technology Research Institute of Sinopec Shengli Oilfield Co., Ltd. features an intelligent drilling rig platform and an integrated drilling operation system.

Overall, China’s intelligent drilling rig technology is still in the early stages of development and needs to integrate modern cutting-edge technologies, combining variable frequency control, tubular handling, top drive, and other technologies.

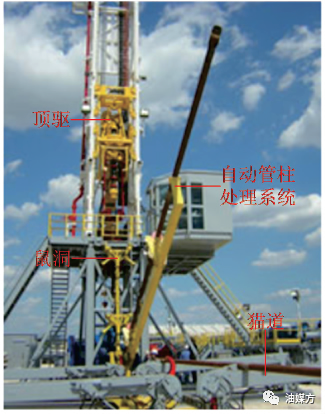

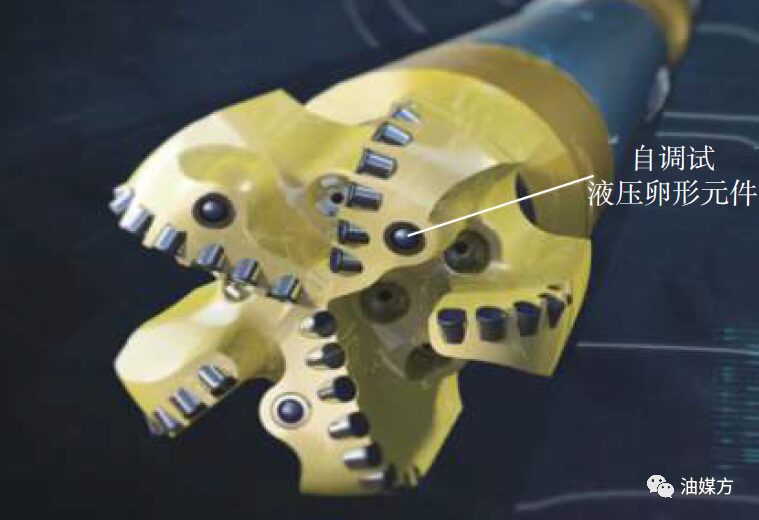

Intelligent drill bits are equipped with intelligent chips and downhole sensors, which can automatically sense formation pressure, formation temperature, drill bit angle, and depth during the drilling process, recognizing the characteristics of the encountered formation in real-time, adjusting the working performance and cutting parameters of the drill bit, keeping it in the best working state.

Baker Hughes’ Terr Adapt drill bit and Halliburton’s Cruzer TM drill bit are representative intelligent drill bits that install automatic adjustment devices, combining sensor feedback information to optimize drill bit cutting depth based on formation structure and target points, reducing stick-slip effects.

Figure 4: Baker Hughes’ TerrAdapt Intelligent Drill Bit

Drilling occurs in high pressure, high temperature, high vibration, high friction, and high corrosion environments, and intelligent drill bits still need breakthroughs in mechanical strength, working conditions, and maintainability.

5. Intelligent Drill Pipe

Intelligent drill pipes are upgrades of ordinary drill pipes, embedding multi-core copper wires wrapped in insulating materials, enabling high-speed information transmission. This closed-loop information transmission method is unaffected by drilling environments, characterized by stable signal transmission and short delays.

(1) The concept of intelligent drill pipes was proposed by Intelli Serv in the United States, utilizing magnetic induction signal transmission methods to invent intelligent drill pipes capable of bidirectional data transmission, with a data transmission rate of 2×106 bit/s.

(2) Based on electromagnetic induction mechanisms, NOV in the United States developed soft connection intelligent drill pipes, which feature fast transmission speeds and large information capacity.

(3) Fiberspar in the United States developed intelligent coiled tubing, embedding power lines and signal lines within the drill pipe, capable of simultaneous data transmission and downhole power supply.

(4) The Engineering Technology Research Institute of China National Petroleum Corporation developed a high-speed intelligent drill pipe, developing key technologies for magnetic coupling cable drill pipes, achieving a transmission rate of 1×105 bit/s.

Overall, intelligent drill pipe technology breaks through the bottleneck of drilling data transmission efficiency, improving the latency of drilling information transmission, and is a key technology for achieving intelligent drilling.

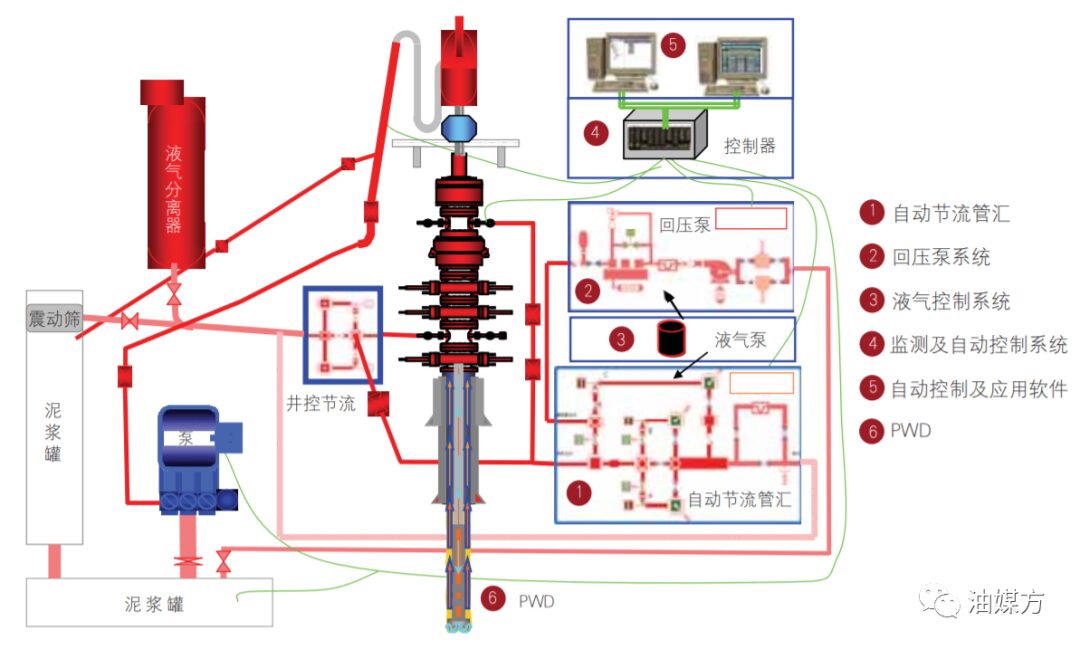

6. Intelligent Pressure Control Drilling Technology

To more effectively address complex downhole issues such as narrow density windows, well surges, losses, collapses, and stuck pipes, intelligent pressure control drilling technology has emerged. This technology features intelligent diagnosis of downhole conditions, automatic adjustment of valve openings, and manual intervention of wellbore pressure. Through a calculation system, precise hydraulic calculations are performed to achieve fine control of wellbore pressure profiles.

(1) Schlumberger’s drilling pressure control system can intelligently adjust pressure, performing real-time dynamic monitoring and adjustment of downhole pressure.

(2) Weatherford’s Victus pressure control drilling system can dynamically analyze downhole pressure online, monitoring drilling fluid pressure and quickly adjusting wellhead back pressure through sensors and throttling control devices.

(3) Halliburton’s Flex mobile integrated pressure control drilling equipment system integrates drilling rig data, intelligently adjusting back pressure based on flow and drill bit depth.

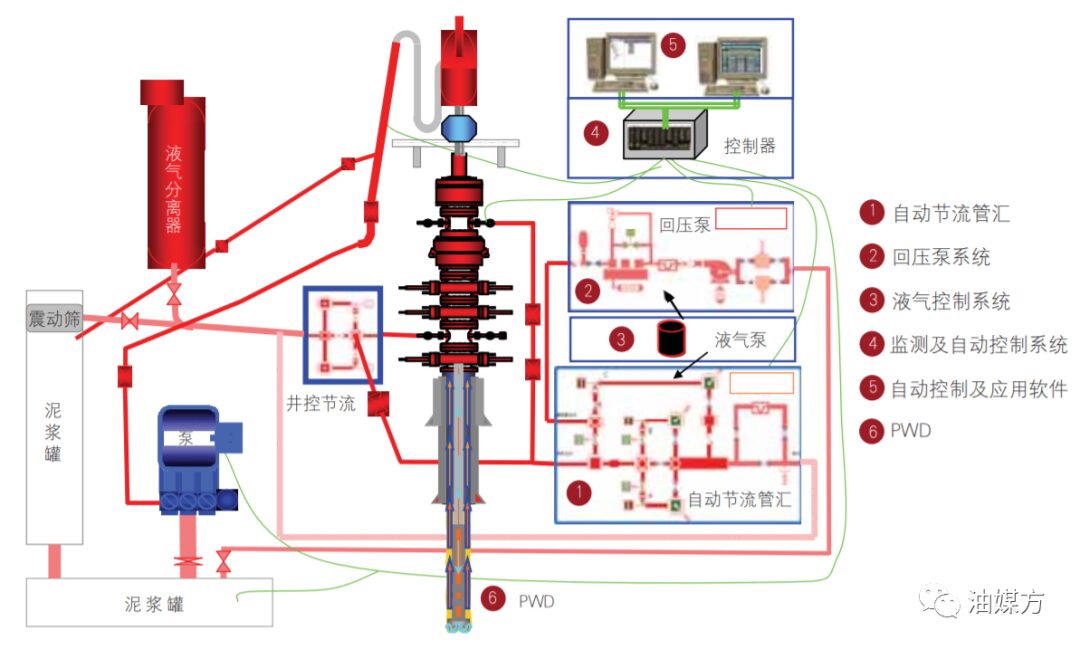

Figure 5: PCDS Fine Pressure Control Drilling System

(4) The PCDS fine pressure control drilling system developed by China National Petroleum Corporation integrates constant bottom hole pressure control and micro-flow control technology, achieving fine pressure control during underbalanced and overbalanced drilling processes.

As drilling environments become increasingly complex and safety and environmental protection requirements become higher, intelligent pressure control drilling technology will be more widely applied.

7. Remote Intelligent Drilling Decision Control System

The remote intelligent drilling decision control system includes data acquisition transmission, information processing, engineering design, real-time monitoring, construction operations, and decision analysis functions, featuring real-time, stable, reliable, and self-learning advantages. This system simulates the drilling process using data warehouses, big data analysis, distributed computing, and collaborative decision-making technologies; optimizes drilling parameters, wellbore structure design, fault diagnosis, risk identification, and prediction using artificial intelligence technologies; and makes real-time analytical decisions based on the intelligent decision-making system, achieving remote real-time control of drilling operations across regions.

Baker Hughes’ SCADA Drill remote control platform features remote data transmission, big data intelligent interpretation, risk prediction, program simulation optimization, and intelligent decision-making functions; it collects drilling historical data, enables machine self-learning, simulates the drilling process, and adjusts drilling parameters.

Norwegian eDilling company’s drilling simulation system includes formation simulation models, hydrodynamic calculation models, tubular mechanics calculation models, wellbore stability analysis models, and drill string vibration models, capable of performing pre-drilling simulation optimization, real-time monitoring and optimization while drilling, and post-drilling analysis.

China’s remote intelligent drilling decision control system still has gaps compared to foreign counterparts and needs to strengthen key technology research in dynamic data intelligent monitoring and analysis, big data integration, and remote expert intelligent decision evaluation.

With the continuous integration of cutting-edge technology and drilling engineering, the future remote intelligent drilling decision control system will have stronger autonomous decision-making capabilities, higher computational accuracy, and more advanced remote control capabilities.

The development of intelligent drilling technology in China still lags behind the world’s advanced level, mainly manifested in the lack of overall development planning; core technology research on obtaining drilling data, high-speed transmission of information between downhole and surface, and drilling big data integration analysis is not systematic; low compatibility of hardware facilities such as intelligent drilling rigs, intelligent drill bits, and intelligent drill pipes; and slow progress in the intelligent development of surface operating systems, downhole rotary steering drilling systems, and remote drilling decision systems.

To rapidly develop China’s intelligent drilling technology, it is necessary to learn from advanced experiences and gradually promote drilling intelligence, with a qualitative leap expected by 2030.

Authors: Yan Tie, Xu Rui, Liu Weikai, Sun Wenfeng, Hou Zhaokai, Shao Yang, the article is organized and published by Oil Media.