Follow 【Finger Motorcycle】 for fresh insights on motorcycle maintenance and repair!

Author: Longxing Tianxia

The maintenance of fuel-injected motorcycles has always left mechanics accustomed to carbureted models feeling at a loss. Today, I will analyze a case where a motorcycle could not start after an ECU replacement, to share some technical insights.

A Neptune motorcycle, as described by a colleague, was received without an ECU or ignition lock. They spent several hundred to buy and install an ECU, and the starter motor turned normally, but there was no high voltage and no spark, with the fault light constantly on. Since I couldn’t see the actual motorcycle, I initially suspected a mismatch between the ECU version and the model.

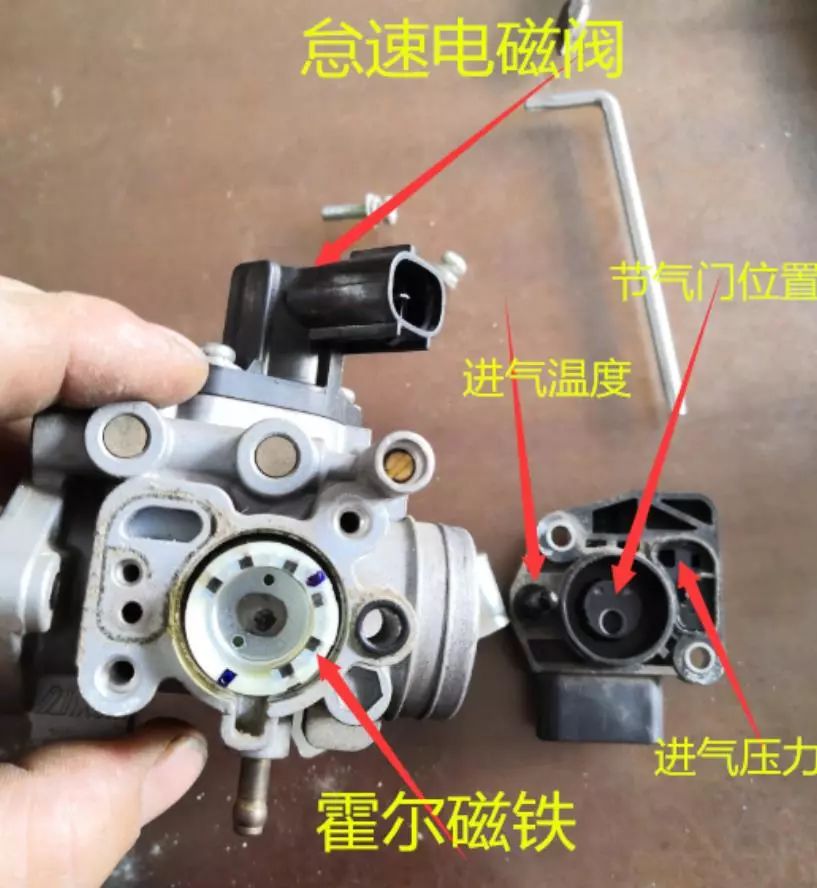

The next day, the colleague brought it to me by van to see what the problem was. Upon receiving the motorcycle, all parts that needed to be disassembled were already taken apart. At a glance, it was evident that this motorcycle belonged to a standard pressure fuel injection system, meaning there was no fuel pump, and fuel injection primarily relied on the injector for direct pressurized injection, referred to as the DCP pump, as shown in the image above.

This type of motorcycle, according to information provided by netizens, generally has two types of ECUs, one from the Three Kingdoms and one from Mitsubishi. Judging by the size of the rubber sleeve that originally fixed the ECU, it was smaller than the Mitsubishi one. Having spent several hundred on it, there must be some basis to convince others whether it is a system mismatch or caused by other reasons.

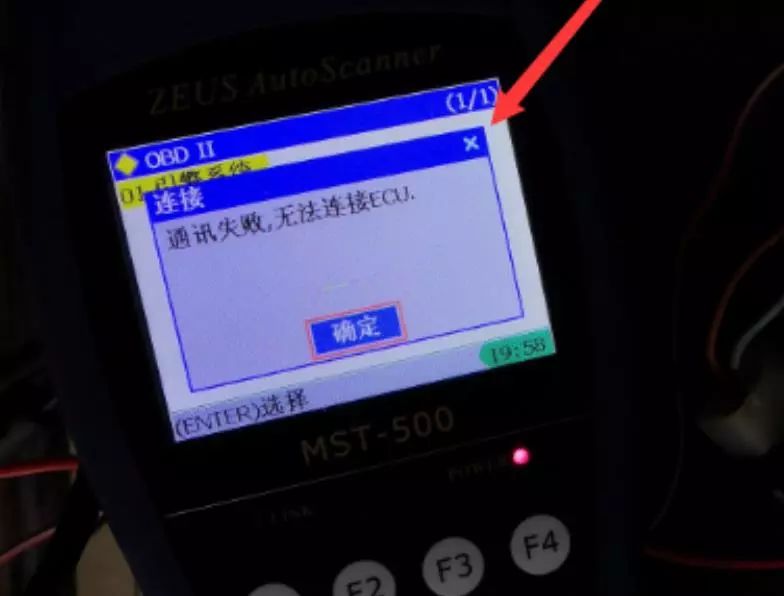

The starter motor can turn normally but does not ignite. Following a systematic approach, I started checking from the outside in, and from simple to complex. Since this motorcycle has a diagnostic port, we first connected the diagnostic tool to check for fault codes, but unfortunately, the system told me it couldn’t connect.

So, I had to first clarify the external circuit. Regarding the order of these steps, I won’t sort them, but will use whatever is convenient. At that time, I checked whether the primary of the ignition coil had 12 volts, and the result was positive.

I checked the ignition lock for 6V voltage and the tilt sensor power for 0.5V voltage. Hmm… this voltage is incorrect; the sensor power supply should be 5V. I also measured the sensor after unplugging it, and the result was the same.

So, what could be causing the low voltage? After some thought, it could be due to incorrect ECU pin definitions or a short circuit in the sensor. This motorcycle’s throttle body is equipped with a three-in-one sensor from the Three Kingdoms. When I unplugged it, the 5V power supply returned to normal, indicating that the three-in-one sensor was faulty. Note this point and check if there are any other related faults elsewhere.

With the spark plug installed, I performed a spark test, and at that moment, the spark was strong, but it still wouldn’t start. I replaced the spark plug and tried again, but it was still unsuccessful. I measured the cylinder pressure at around 10KG. Strange, there is spark and pressure, but it won’t start?

I considered whether the fuel supply was inadequate. I removed the DCP pump, placed a towel underneath, and checked the fuel atomization effect and amount. The atomized fuel and pressure felt like it was being sprayed out, indicating at least some signs of life for the motorcycle. However, the motorcycle showed no indication of starting.

Could it be that my earlier intuition was correct, that the ECU version was wrong, causing incorrect ignition and injection timing? I planned to remove the fan cover to manually mark the piston top dead center, find the ignition timing, and check it with an ignition timing light.

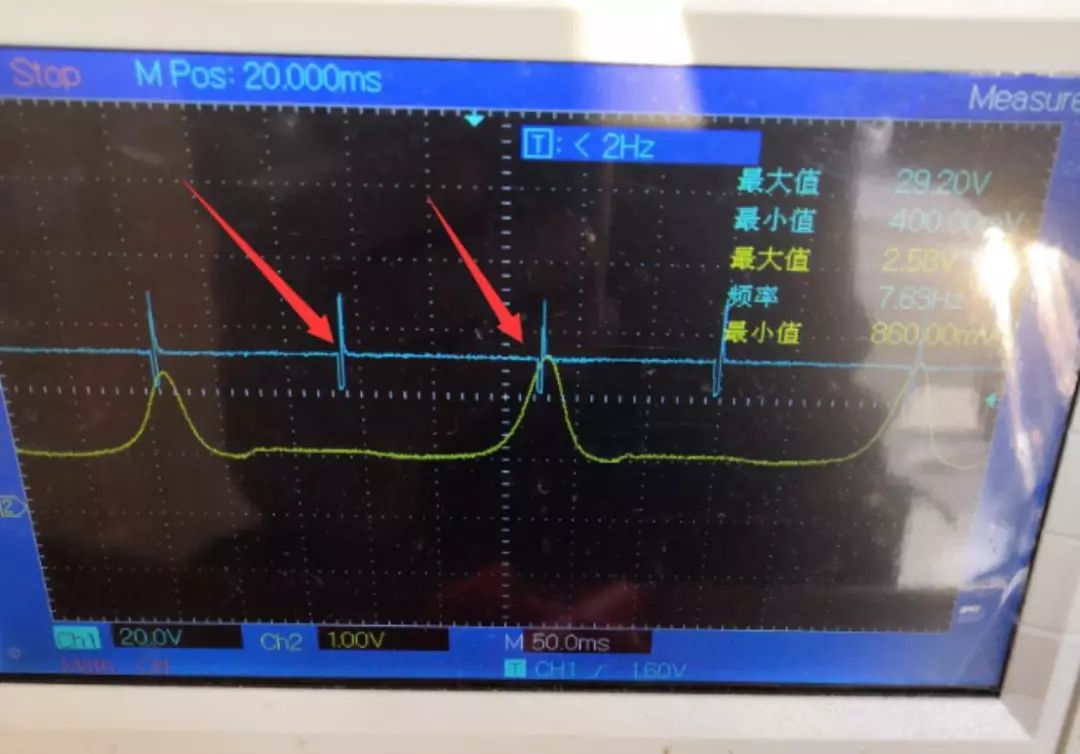

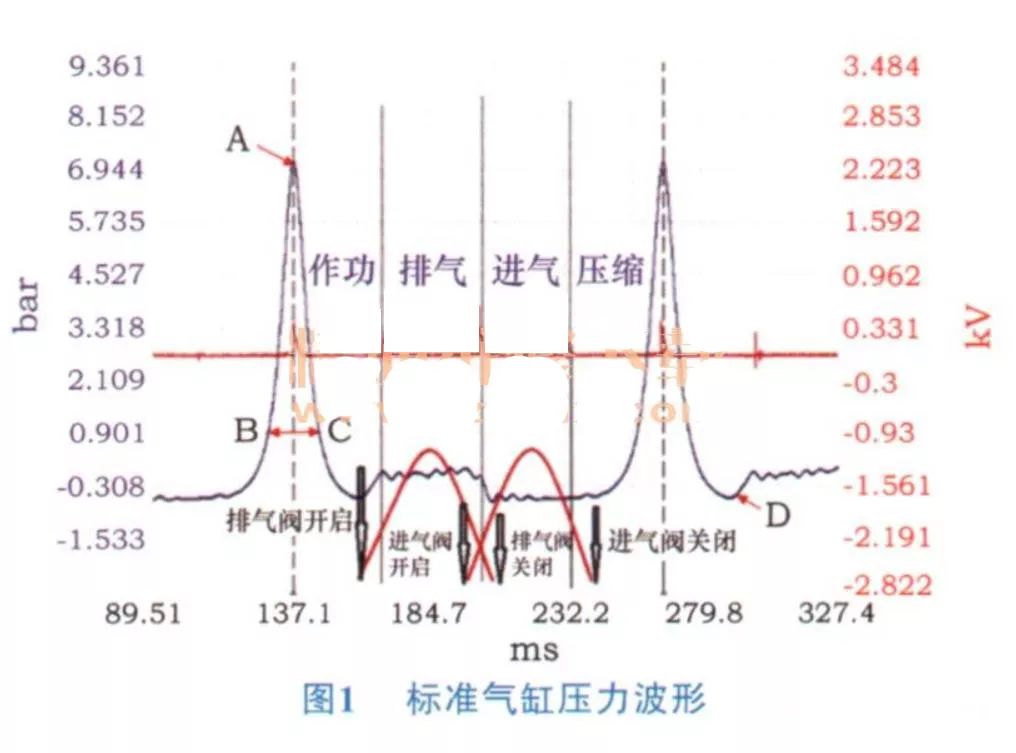

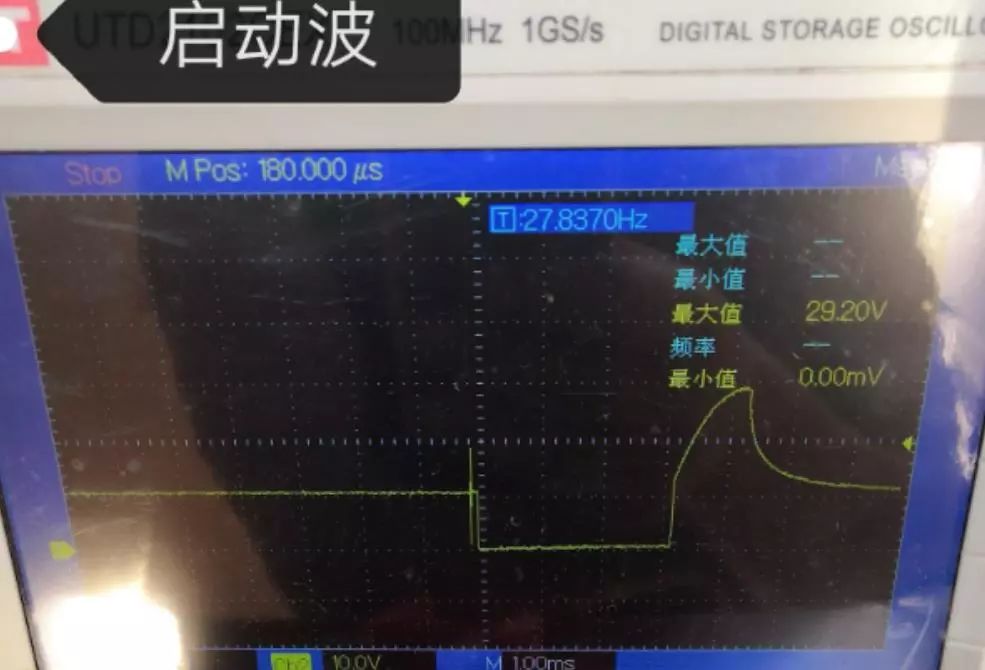

When I removed the fan cover, I was stunned; besides the cooling fan blades, I couldn’t see anything else! The next day, I brought a oscilloscope home to capture the cylinder pressure waveform and injection waveform. The yellow in the image below represents cylinder pressure, and the blue represents fuel injection.

Based on the generated waveforms, analyzing the angles at which fuel injection occurs should allow the motorcycle to start. The diagram below shows the principle framework.

This means that, from the waveform perspective, such ignition and injection angles should definitely allow the motorcycle to start, but why is it not starting?

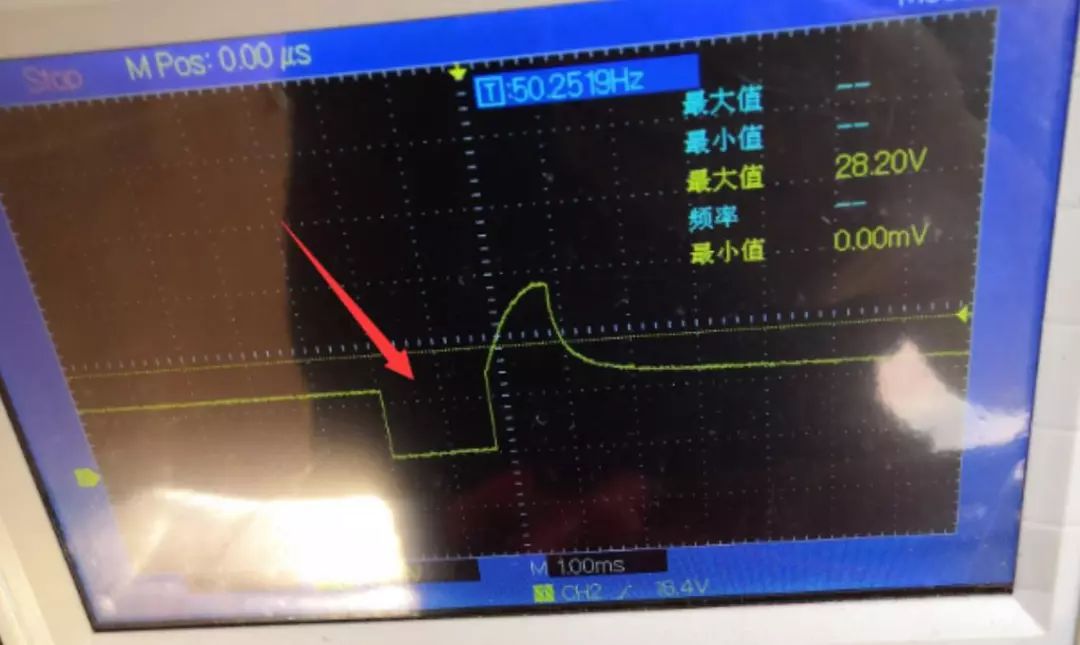

When capturing the fuel injection waveform separately, upon turning on the ignition lock, there will be a 2ms fuel injection pulse width, which does not spray fuel but serves to purge air.

During startup, there is a fuel injection pulse width of about three to four milliseconds. In a pressure fuel injection system, the cold start pulse width should be around 5 to 10ms.

At this point, I had an epiphany. I applied the methods I used for carburetors, suspecting that the fuel supply was slightly lacking. I removed the air filter and sprayed some cleaner directly into the intake while cranking the starter. This time, the motorcycle started.

Since I found that the 5V power supply only returned to normal after unplugging the three-in-one sensor, I proceeded to measure the three-in-one sensor.

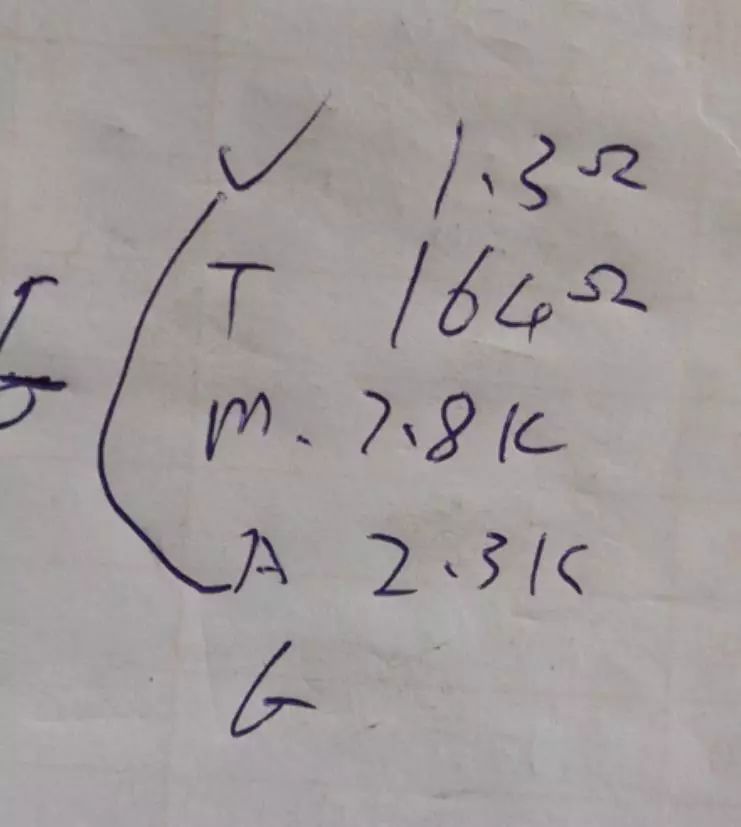

The three-in-one sensor is internally represented by V, T, G, m, A. After measurement, I found that V was the 5V power supply, T was the throttle position, G was the ground line, m was the pressure sensor, and A was the intake temperature sensor. The image below shows the resistance values of each pin to the ground.

From the diagram, it can be seen that only the throttle power line and signal line have a low resistance value to ground, confirming that there is a short circuit in the throttle position sensor. After communicating with the customer, I replaced the three-in-one sensor, and the fault was resolved.