With the arrival of Industry 4.0, the manufacturing sector is entering a new digital era. Under this backdrop, industrial enterprises need to build new intelligent factories to support the upgrade of traditional industries to intelligent manufacturing. Integrating new generation information technologies such as the Internet of Things, big data, and 5G into various processes, production, and logistics has become a necessary industry trend to improve quality, reduce costs, and increase efficiency.

By deploying industrial IoT platforms and solutions, industrial enterprises can achieve comprehensive perception and insight from the bottom production line, workshop, to factory assets, with full data collection and intelligent analysis. The Internet of Things assists industrial enterprises in creating value in dynamically changing user demand scenarios, becoming the “last mile” for industrial enterprises to achieve comprehensive digitalization, informatization, networking, and intelligence.

However, when industrial enterprises are building digital factories, they often face the following four major challenges and pain points:

-

Industrial Access: Industrial equipment involves many types of protocols, with a large number of field points. How to efficiently access data and eliminate information silos between different business systems?

-

Industrial Data: Poor data quality from devices, large amounts of data; issues with large-scale storage, computation, and analysis of all industrial data; how to connect IT and OT data?

-

Industrial Analysis: The workshop production line has accumulated a large amount of equipment and production data, but lacks integrated management and convenient computational tools for the fusion analysis of equipment and business data. How can enterprises effectively drive quality improvement, cost reduction, and efficiency enhancement with data?

-

Industrial Intelligence: Models cannot be built solely from the data layer; how to integrate industrial mechanisms with artificial intelligence?

In response to these challenges, the Tencent Cloud IoT team, based on years of technological accumulation on the IoT platform and practical experience serving hundreds of enterprises, has launched the industrial IoT solution for the industrial sector, combined with Tencent Cloud’s industry-leading big data processing and analysis capabilities.

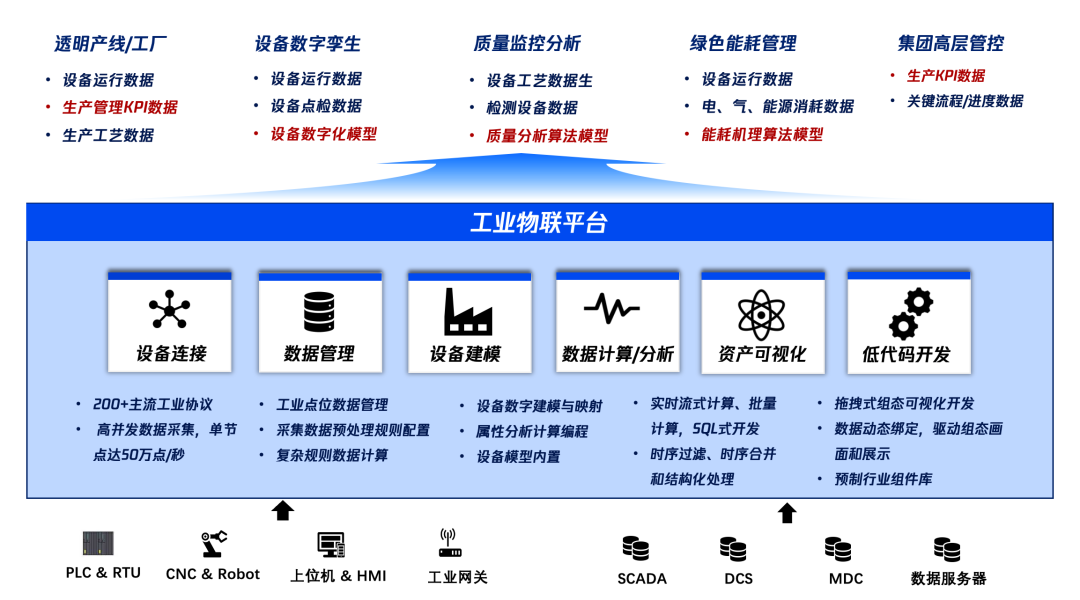

This solution targets key national enterprises in the automotive, electronics, semiconductor, and equipment manufacturing sectors, providing core functions such as device connectivity, time-series data storage, asset modeling, stream computing analysis, time-series analysis, offline analysis, and asset visualization. Meanwhile, application layers work with partners to provide industrial application solutions such as production management, quality management, production scheduling, warehouse management, and intelligent monitoring, helping enterprises build the infrastructure for digital transformation.

Solution Advantages

200+ Mainstream Industrial Protocols, Stable Data Collection Access

Based on an edge integrated machine (with built-in industrial protocol drivers and MQTT receivers) + IoT platform (IoT Explorer) providing stable industrial point data collection and reporting, with a single machine supporting up to 50W points/s for simultaneous collection, achieving high performance scalability.

Extreme Performance, Lower Costs

Compared to traditional industrial IT data architectures, the industrial IoT platform is based on Tencent Cloud’s big data products, providing real-time data warehousing and streaming computing capabilities, offering a more stable data query processing and lower storage cost technical solution for IoT customer scenarios.

Plug and Play, Flexible Analysis

Based on the IoT platform + big data analysis capabilities, a standard industrial IoT platform has been created for manufacturing enterprises, supporting flexible deployment in various ways and ready to use out of the box. It provides low-threshold IoT analysis functions, significantly lowering the development threshold for industrial data.

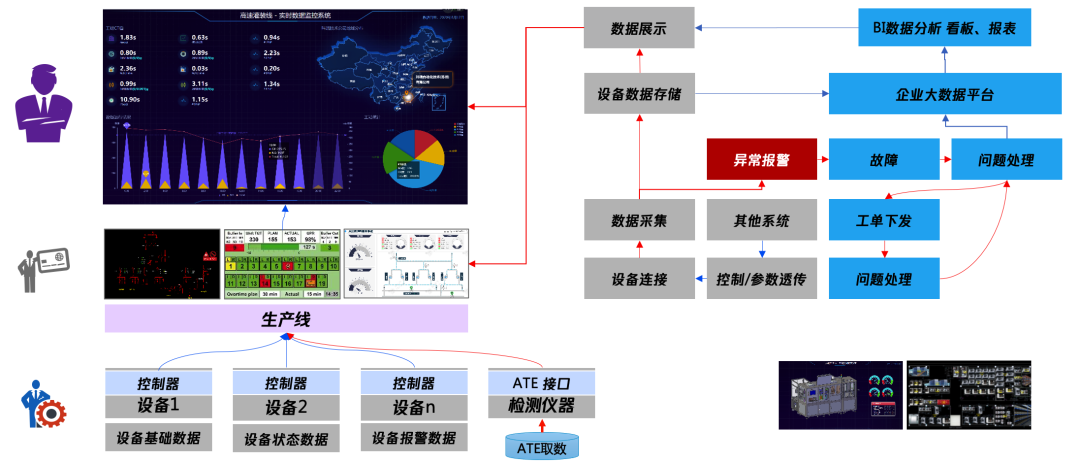

Application Scenarios

Based on IoT technology, connect production manufacturing equipment to achieve industrial equipment data collection, status monitoring, maintenance work order management, alarms, OEE analysis, etc. It can also link with APS & MES systems to automatically dispatch production plans, manage recipes, and validate error-proofing, fully enhancing the collaborative efficiency of equipment and systems.

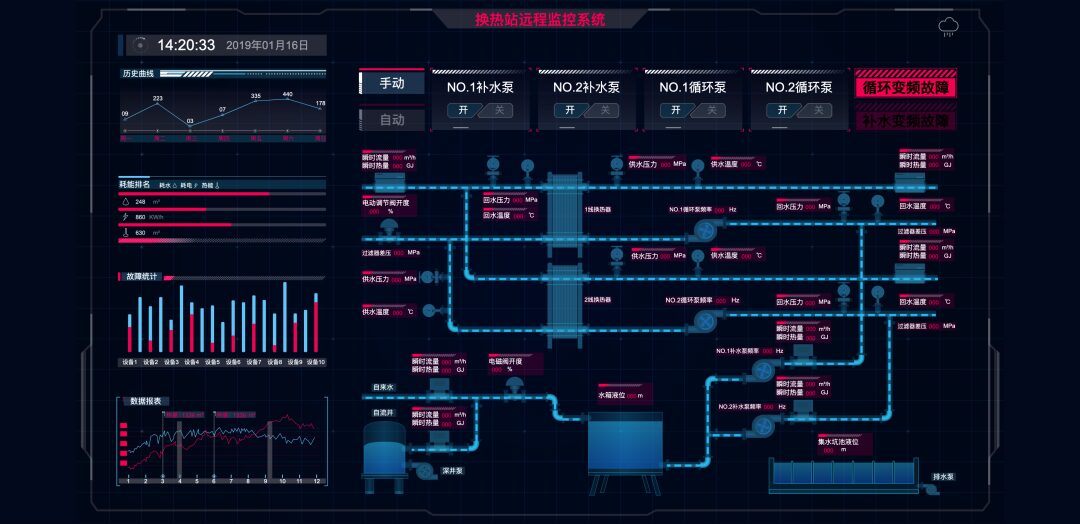

Based on the IoT device data analysis capabilities, process and compute key production indicators to obtain real-time equipment asset data and analysis results. Through monitoring screens and equipment dashboards, achieve asset visualization monitoring to have a comprehensive understanding of factory operating status.