If we compare the engine to the “heart” of a car, then the car’s “brain” should be the ECU. What is ECU? How does it work? This article provides a detailed analysis.

What is ECU? ECU has two full names: Engine Control Unit and Electronic Control Unit. It is easy to see that the former refers to “engine control unit” while the latter is “electronic control unit.” These are two concepts that can be easily confused, and today we will mainly analyze the “Engine Control Unit”.

1The Emergence of ECU

Before 1967, the fuel supply system of gasoline engines was managed by carburetors, which is completely different from today’s electronic fuel injection engines. Carburetors use the pressure difference before and after the throttle to draw fuel, which not only fails to accurately control the fuel supply but also restricts the improvement of the car’s performance and environmental protection. Companies like Bosch developed electronic fuel injection systems, with the earliest BOSCH electronic fuel injection system being D-Jetronic, followed by K-Jetronic and L-Jetronic. After the introduction of electronic technology, BOSCH developed several electronic management fuel injection systems, among which KE-Jetronic is the electronic injection technology widely used today. Although the product names vary among companies, their structures are largely similar.

The working characteristic of the electronic fuel injection system is to inject fuel “quantitatively and timely”. How much fuel the engine needs and when it should be injected is directly related to the engine’s speed, air flow, and various other parameters, including water temperature, oil pressure, and more. How to process so many parameters and issue fuel injection commands to the injection system? This requires the intervention of the engine control unit, and thus the ECU was born.

2Working Principle of ECU

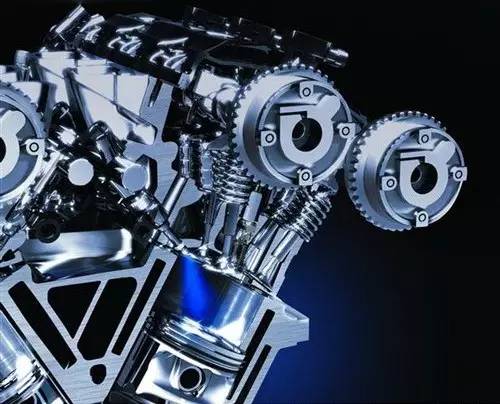

Similar to an ordinary microcontroller, the ECU consists of a microprocessor, memory, input/output interfaces, analog-to-digital converters, and integrated circuits for shaping and driving. The role of the ECU is to calculate the vehicle’s operating conditions through various sensors, thereby controlling multiple parameters of the engine, including ignition, air-fuel ratio, idle speed, and exhaust gas recirculation. Its operating temperature ranges from -40 to 80 degrees Celsius, and it can withstand significant vibrations, making the probability of ECU failure very low. Additionally, the ECU has self-diagnosis and protection functions. When the system malfunctions, it can automatically record fault codes in memory and adopt protective measures by reading alternative programs from the inherent program to maintain engine operation, allowing the vehicle to reach a repair shop.

How does the ECU work? Simply put, it is a process of command from a general: “thinking”, “commanding”, and finally “confirming”.

The “reconnaissance” is done by the sensors, which are responsible for “scouting” the entire engine. There are dozens of sensors on an engine, both large and small. The throttle position sensor, crankshaft speed sensor, oxygen sensor, crankshaft position sensor, camshaft position sensor, intake temperature sensor, water temperature sensor, and knock sensor are the most basic sensors in a car engine. Sensors are ubiquitous; they collect relevant information and transmit it to the ECU in the form of electrical signals. After being converted to digital signals by the analog-to-digital converter (A/D), the ECU processes the data to determine the current operating state of the engine. This is the “thinking” process of the ECU.

What standards does the “thinking” process rely on? Computers do not have thoughts; they rely on the programs stored in ROM. This is akin to software. When data is transmitted to the ECU, the existing data in the ROM program is compared with the collected signals to derive adjustment methods. This set of programs is the soul of the ECU, and its writing is based on extensive experimental data, often requiring bench tests and road tests to establish. Typically, tuners modify the ECU program by rewriting or revising the ROM program to change the ECU’s calculation criteria.

Let’s delve deeper into this process:

The amount of fuel supplied is calculated based on the duration of the fuel injector’s injection time. The fuel computer (ECU) calculates the required injection time based on the air flow, engine speed, and various compensation signals provided by the sensors, using the originally set fuel supply program, which can be represented graphically.

The fuel injection time calculated by the ECU is the sum of the “basic injection time”, “compensation injection time”, and “invalid injection time”, measured in microseconds (ms), where 1 ms = 0.001 seconds. The amount of gasoline injected by the fuel injector in a unit time is determined by the size of the injector’s aperture and the injection pressure.

1. Basic Injection Time

The basic injection time is determined by the intake volume (referring to weight) and engine speed. When you press the accelerator pedal, it controls the angle of the throttle valve; the larger the angle, the greater the intake volume. The fuel computer calculates the required fuel amount and corresponding injection time based on the intake volume measured by the air flow meter and the current engine speed, comparing it with the pre-set fuel supply program.

2. Compensation Injection Time

Compensation injection, commonly referred to as “acceleration”, is determined by various sensors detecting the engine’s current operating conditions and load, sending signals to the computer (ECU), which then calculates the additional fuel required to maintain stable and smooth engine operation. Setting the compensation injection program is a complex task and varies from vehicle to vehicle.

Generally speaking, the compensation injection program includes the following items: cold start compensation, warm-up compensation, idle restart compensation, high-temperature compensation, acceleration compensation, high RPM/high load compensation, theoretical air-fuel ratio feedback compensation, and fuel cut control.

3. Invalid Injection Time

There is a delay time from when the injector is energized to when it fully injects fuel, known as “opening delay”; similarly, there is a delay time from when the coil is de-energized to when the injection stops completely, known as “closing delay”.

Since the opening delay is longer than the closing delay, the actual fuel amount supplied will be less than required, and the difference between the opening delay and closing delay is referred to as “invalid injection time”. To obtain the correct fuel amount, the invalid injection time must be accounted for, meaning that after calculating the fuel amount, the amount injected during the invalid injection time must be added to achieve the desired result. Therefore, the invalid injection time can also be viewed as part of the compensation injection.

Of course, the ECU is not static. Another function of the memory is akin to an aircraft’s “black box”, which can record the data of the car’s operation. Many ECUs have a “learning” capability; under normal circumstances, the memory continuously records data during driving, forming the ECU’s learning program to provide optimal control status that adapts to the driver’s habits. This program is also called the adaptive program. However, since it is stored in memory, similar to error codes, all data will be lost if the battery is disconnected and power is lost. The ECU can constantly learn from the data recorded in memory about the driver’s driving style, thus becoming more user-friendly. Additionally, if a fault occurs, information can be retrieved from memory to assist with repairs.

After completing the “thinking” process, the next step for the ECU is to “command”. The components controlled by the ECU include the fuel injectors, which adjust the amount and timing of fuel injection, while the fuel pump is responsible for supplying fuel; the ignition controller and ignition coil also operate under the ECU’s control. After this, the ECU needs to receive data again to confirm the end of a closed-loop control.

With the advancement of automotive technology today, the ECU bears an increasing number of responsibilities. Technologies like i-VTEC that feature variable valve timing require additional camshaft position sensors and calculations by the ECU to adjust the camshaft phase. Particularly with BMW’s Double-VANOS and other continuously variable valve timing systems, the ECU must perform precise calculations to control their phase and valve lift. Currently, in some mid-to-high-end cars, ECUs are applied not only in engines but also in many other areas. For instance, anti-lock braking systems, four-wheel drive systems, active suspension systems, airbag systems, and automatic transmissions all require separate control systems. An increasing number of ECUs are appearing in vehicles, and the many devices added to cars require ECU management. The traditional “Engine Control Unit” is no longer sufficient for the development of the times, becoming a module of the overall vehicle control system. Therefore, today we prefer to refer to the ECU as the “Electrical Control Unit”, i.e., the electronic control system. With the increasing automation of automobiles, the number of ECUs will continue to rise, and the wiring will become increasingly complex. To simplify circuits and reduce costs, the information transfer between multiple ECUs in a car will adopt a technology known as multiplexed communication network technology, forming a network system of the vehicle’s ECUs, which is the CAN data bus, as will be discussed further below.

3Upgrading the ECU

1. Feasibility of ECU Modification

ECU manufacturers are all international multinational companies, such as BOSCH, SIEMENS, MM, etc. Their products are sold worldwide. Due to differences in gasoline quality, temperature, atmospheric pressure, humidity, and engine types in each country, the ECU program software must be set to meet the conditions of each country. Modern cars need to adapt to various weather and environmental conditions (such as plateaus, deserts, extreme cold, and poor-quality gasoline) and various drivers’ different requirements. At the same time, it must ensure that under such complex conditions, it can still drive smoothly and comply with strict exhaust emission and fuel consumption standards. Therefore, in most cases, the original ECU’s program is a best compromise that meets many conditions, ensuring it does not become unsuitable for the environment, leaving much room for modification. Additionally, when automotive brand manufacturers tune engine parameters, they generally consider the engine’s ability to function normally even in the harshest environments or under long-term neglect, meaning that manufacturers always set engine outputs conservatively. Therefore, as long as the owner ensures regular maintenance of the car, they can achieve greater output through recalibrating engine parameters to enjoy an extraordinary driving experience.

Taking the air-fuel ratio (AFR) as an example, the factory programmer may set the AFR to be slightly leaner (i.e., less fuel, more air) under certain driving conditions (such as cruising) to reduce fuel consumption, in order to meet some countries’ fuel consumption testing standards. However, the original ECU’s AFR is mostly set at the ratio mentioned above of 1:14.7, as this is the easiest ratio to meet exhaust standards. But for most engines, the AFR that produces maximum power is within a richer mixture (i.e., more fuel, less air). Similarly, to broaden the fuel adaptability of the car (different fuel grades in different regions), the ignition advance angle set by the factory is generally adaptable to lower-grade fuel (the engine outputs different power at different ignition advance angles). This means that the current ignition advance angle of your engine may not match the best pairing with the fuel grade you are using. If the original program can be modified towards performance, it can increase horsepower by around 5-8%, and some turbocharged cars can achieve up to 15%.

2. Methods of ECU Modification

ECU chip modification: When manufacturers design an engine, they have already burned the pre-set fuel supply program onto the ROM. This program is usually a product of compromises regarding fuel consumption, pollution, and operational smoothness, and it is unchangeable. Because it is unchangeable, if you want to change the fuel supply program, you must switch to a different mode of ROM. Professional modification shops usually supply modified computer chips for various models. During modification, the original computer chip must be removed (usually the original fuel computer’s ROM is directly soldered onto the circuit board), an IC socket is soldered on (to facilitate future replacements), and the modified chip is inserted. The resulting fuel supply program remains fixed; it is merely a correction of the original program. One important aspect is that it can delay or even cancel the fuel cut control time in the compensation injection program.

It is important to note that each modified chip has its set applicable conditions (i.e., the degree of modification). When modifying, you must choose a chip that is close to your car’s modification status to achieve the best results; otherwise, it may have the opposite effect. The selection of chips should only be done after consulting experienced modification shops. Each chip has its own fuel supply program, and clever readers might wonder: what if two or three are installed? Indeed, there have been cases where modification shops have installed two or three different fuel supply mode chips on the same circuit board, allowing the driver to switch between desired fuel supply modes with an external switch, similar to switching between P, E, and S modes on an automatic transmission, to meet various needs of the driver.

ECU computer programming: This is a more professional aspect of ECU system modification. The most familiar in the domestic modification scene is the HALTEC computer. Through this computer, owners can set the optimal fuel supply program according to the degree of modification of their engine, in conjunction with the measurement of the air-fuel ratio, adjusting the previously mentioned basic injection program and various compensation injection programs using a laptop. Its greatest difference from chip modification, and its greatest advantage, is that if the engine undergoes further changes or modifications in the future, and the original fuel supply program becomes unsuitable, it can be immediately resolved through program adjustments. After computer programming, the original fuel supply program becomes obsolete, but higher-level computers can retain all the functions of the original car’s sensors, meaning that various fuel supply compensation programs can operate normally and can be adjusted without sacrificing operational smoothness and practicality for high performance.

The main difficulty in modifying a programmable ECU does not lie in installation but in setting and optimizing the fuel supply program. This often requires experience and instruments, achieved through continuous testing. Currently, modification shops typically select a basic mode as a foundation and then gradually adjust it through actual operation and testing until satisfied.

3. Common Issues During ECU Modification

Unlike other mechanical systems, the functionality and working principles of the ECU are “invisible”, and most automotive repair shops, even 4S shops, do not understand or cannot repair or resolve ECU-related issues, creating a sense of mystery around the ECU. Here are a few common issues encountered during ECU flashing:

1) Use the original ECU or a newer ECU?

For general civilian modifications, I personally prefer using the original ECU for modifications. The original ECU has very strong functionality, and its program is developed through long-term data accumulation and countless tests by the manufacturer’s engineers. It can protect the engine under all circumstances without generating fault codes or warning lights, and it will not cause conflicts with other systems like ABS, anti-slip, and anti-theft systems. Furthermore, it will not delete important functions from the vehicle. On the other hand, the modification cost is relatively low.

2) Regarding the degree of ECU modification and tuning style

From a performance modification perspective, ECU modification is an indispensable step. The ECU can help the engine achieve optimal mechanical functionality, but it cannot exceed the limits allowed by the original design. For instance, when professional racing teams develop racing engines, they first design the combination of camshafts, pistons, connecting rods, etc., determining the engine’s compression ratio and maximum RPM, and only then consider the ECU. Without a powerful engine, no matter how capable the ECU is, it is ultimately futile. Therefore, for ECU program tuning, unless used in racing, the focus is generally not solely on maximizing horsepower at wide-open throttle. More attention is usually paid to the acceleration capability and throttle response of the vehicle at low to mid RPMs, as civilian cars rarely operate at full throttle and maximum RPM. Thus, the emphasis is on achieving smooth and progressive power delivery in the 2000 RPM to 4000 RPM range, under half-throttle conditions, rather than striving for a few extra horsepower at 7000 RPM. In these areas, the goal is to create a smooth and progressive power and torque curve, allowing drivers to feel the throttle is particularly responsive and powerful. While maximum horsepower figures may attract attention in marketing, in real-world conditions, no one enjoys driving a car that accelerates unevenly. Therefore, there is no need for civilian modified cars to reach the power levels of racing cars; a more accurate perspective should be whether such modified products can improve power output while ensuring vehicle safety.

3) Will ECU upgrades affect the lifespan and safety of the vehicle?

Many people may wonder whether ECU upgrades will affect the lifespan and safety of the vehicle. In fact, there is no need to worry; flashing the ECU merely performs a comprehensive optimization of the vehicle’s computer data, rather than striving for a single indicator’s improvement or fully unleashing the engine’s capabilities. Its optimization is based on ensuring longevity, economy, and safety, providing the vehicle with a comfortably operational space. However, there is another situation where, due to cost and technical levels, some car enthusiasts may resort to installing some parts colloquially known as “secondary intake” or “fuel addition” to increase the amount of fuel and air entering the engine. These parts essentially bypass the original sensors or alter the sensor voltage to “deceive” the ECU, leading to changes in the air-fuel ratio entering the engine without the ECU’s knowledge, improving the engine’s power output under certain conditions. This incomplete modification approach can lead to other side effects and even potential safety issues, while the legitimate ECU modification method, although costlier, can avoid many adverse side effects.

4) Differences in ECU settings between street cars and racing cars

ECU settings are generally divided into two types: street cars and racing cars. For racing cars, since the fuel, venue, and driver factors are predetermined, the computer’s focus is on handling changing weather, temperature, and other environmental factors. Street cars, however, are much more complex, as there are no restrictions on driving time, and fuel quality can vary even when using high-quality fuel. Even if both use high-quality fuel, different gas stations may yield different results. Compared to racing cars, street car modifications need to consider safety factors more, so the computer settings must retain some leeway. After comprehensively considering the driver’s driving style and vehicle characteristics, settings can be made. Moreover, even with identical conditions and vehicles, variations may occur, so using the same data for settings may not yield the best results.

5) Points to note during ECU flashing

Many car owners focus solely on the horsepower output without considering torque, which is a common issue. In reality, modifications should not be mindlessly driven by horsepower; before modification, it is essential to clarify the vehicle’s intended use and the owner’s driving habits.

For modification shops, when modifying the ECU, it is advisable not to focus solely on fuel injection timing but also to ensure that fuel supply is adequate. Attention should also be paid to the timing of ignition, as the ignition advance angle is extremely important. Furthermore, any hardware added to the vehicle must be understood regarding its characteristics so that it can be effectively paired with the ECU modifications to achieve optimal results.

Additionally, if the engine uses a high-angle camshaft, as it alters the timing of valve opening and closing, programming becomes significantly more challenging. Precise calculations and adjustments are required. The ability to fully utilize the performance of modified parts depends entirely on ECU adjustments, but changing the engine’s characteristics by altering ECU data is a very difficult task.

4The Future Trends of Automotive Control

Let’s count how many systems require control systems. Automatic transmissions, ABS systems, in-car entertainment systems, four-wheel drive torque distribution systems, active suspension systems, airbags + seatbelt systems, etc. So many systems have their own sensors and processors, performing separate calculations without interfering with each other. However, the automatic transmission and engine need to cooperate; for example, the engine needs to reduce power during shifting, and full throttle requires the transmission to kick down to a lower gear. Under various conditions, both need to share a lot of data, such as the crankshaft speed of the engine. Establishing a new set of sensors for the automatic transmission would waste costs and be impractical. The best solution is to have the transmission and engine ECUs share data, which has led to the development of an information network system between ECUs—the CAN data bus. The same CAN data bus is also adopted in chassis electronic devices, such as four-wheel drive torque distribution systems and ABS, sharing many chassis sensor parameters.

The development of the CAN data bus will inevitably integrate all control systems. There is a saying that future ECUs will be powerful computer systems that integrate all components requiring management, including the engine, automatic transmission, ABS systems, in-car entertainment systems, four-wheel drive torque distribution systems, active suspension systems, airbags + seatbelt systems, etc. We can enjoy automotive audio systems, play PC games, receive GPS signals, and even a cup holder will be managed by the ECU.

Even more interesting is the notion that future ECUs may establish an open interactive software system, similar to the Windows operating system, on which a plethora of engine management systems, transmission management systems, ABS systems, etc., can be installed. At that time, the “ECU” management system of the engine will merely be a software that can be updated in real-time; you can choose version 1.1 or version 2.0. Of course, you will also need to install a firewall to prevent hackers from intruding.

(Source: China Automotive Technology Information)