Source: SiP and Advanced Packaging Technology

Original Author: Suny Li

The differences and similarities between SoC (System on Chip), SoIC (System on Integrated Chip), and CIC (Cubic Integrated Circuit) will be compared and interpreted today.

SoC

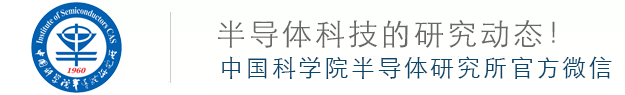

SoC stands for System on Chip, which is a system or product formed by combining multiple integrated circuits with specific functions on a single silicon chip, containing a complete hardware system and its embedded software.On an SoC, processors (including CPU, DSP), memory, various interface control modules, and various interconnect buses are integrated. The following diagram shows the layout of the Kirin 980 SoC. SoC enables the functionality of an electronic system to be completed on a single chip, whereas before the advent of SoC, this often required one or more circuit boards, along with various electronic components, chips, and interconnections working together.SoC achieves a high level of integration of functions on a single chip, significantly improving the functional density compared to traditional board-level systems.

SoC enables the functionality of an electronic system to be completed on a single chip, whereas before the advent of SoC, this often required one or more circuit boards, along with various electronic components, chips, and interconnections working together.SoC achieves a high level of integration of functions on a single chip, significantly improving the functional density compared to traditional board-level systems.

SoIC

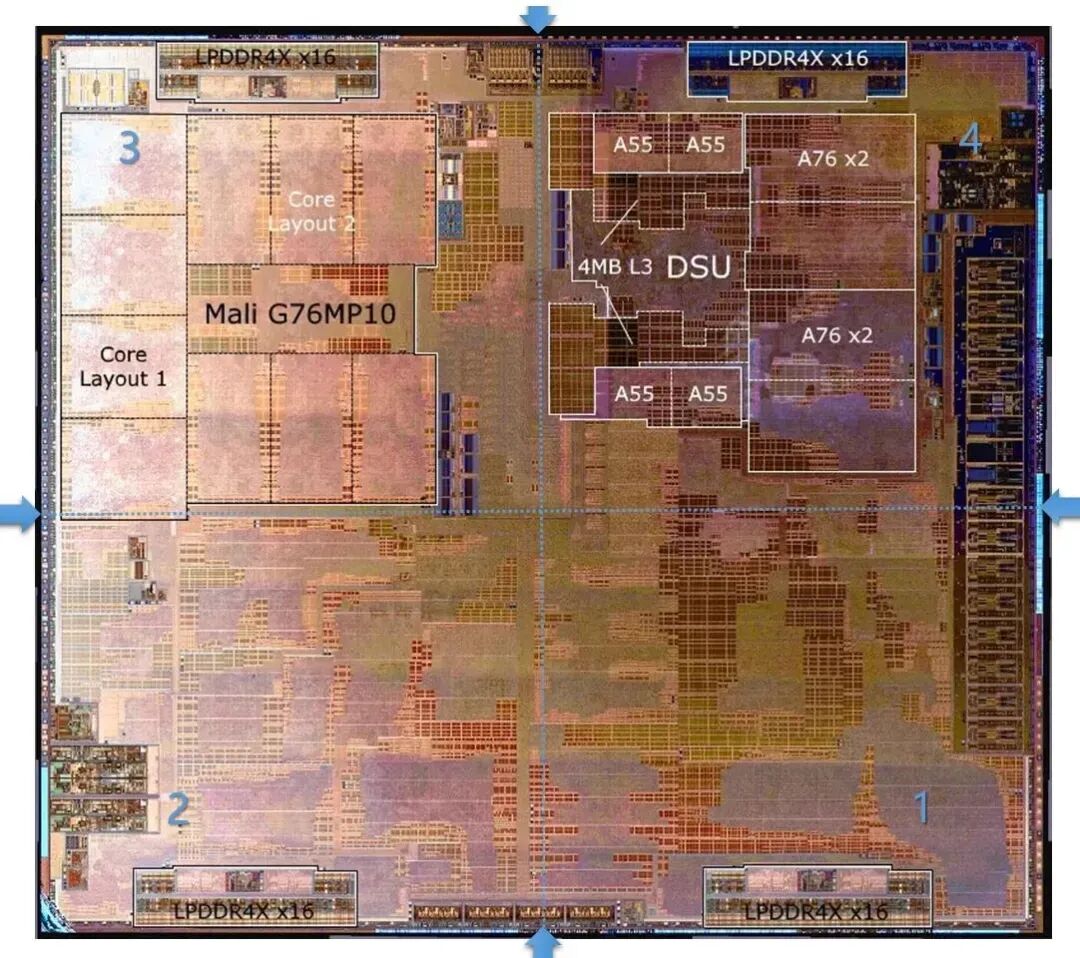

SoIC (System on Integrated Chips) is TSMC’s latest advanced packaging technology. The most distinctive feature of this technology is its no-bump bonding structure, which allows for higher integration density and better performance.SoIC assembles multiple chips using hybrid bonding, achieving volume and performance metrics equivalent to a single SoC.Comparing the SoC and SoIC in the diagram below, we can see that SoIC has at least two advantages over SoC: 1) heterogeneous integration, 2) higher functional density. SoIC-1, SoIC-2, and SoIC-3 can be produced using different process nodes and then assembled through hybrid bonding, supporting heterogeneous integration, thus providing greater flexibility. Additionally, SoIC has more transistor layers; in the diagram, I have highlighted the transistor layers. It can be seen that SoC has one transistor layer, while SoIC has two. Under the same process conditions, SoIC has twice the number of transistors compared to an SoC of the same volume, resulting in a functional density that is also double that of SoC. As the number of stacked layers increases, this advantage becomes even more pronounced.

SoIC-1, SoIC-2, and SoIC-3 can be produced using different process nodes and then assembled through hybrid bonding, supporting heterogeneous integration, thus providing greater flexibility. Additionally, SoIC has more transistor layers; in the diagram, I have highlighted the transistor layers. It can be seen that SoC has one transistor layer, while SoIC has two. Under the same process conditions, SoIC has twice the number of transistors compared to an SoC of the same volume, resulting in a functional density that is also double that of SoC. As the number of stacked layers increases, this advantage becomes even more pronounced.

CIC

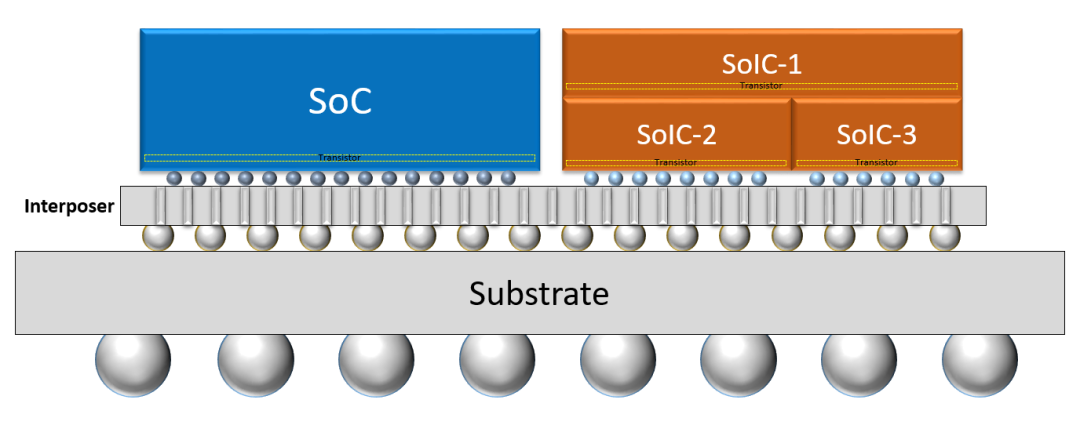

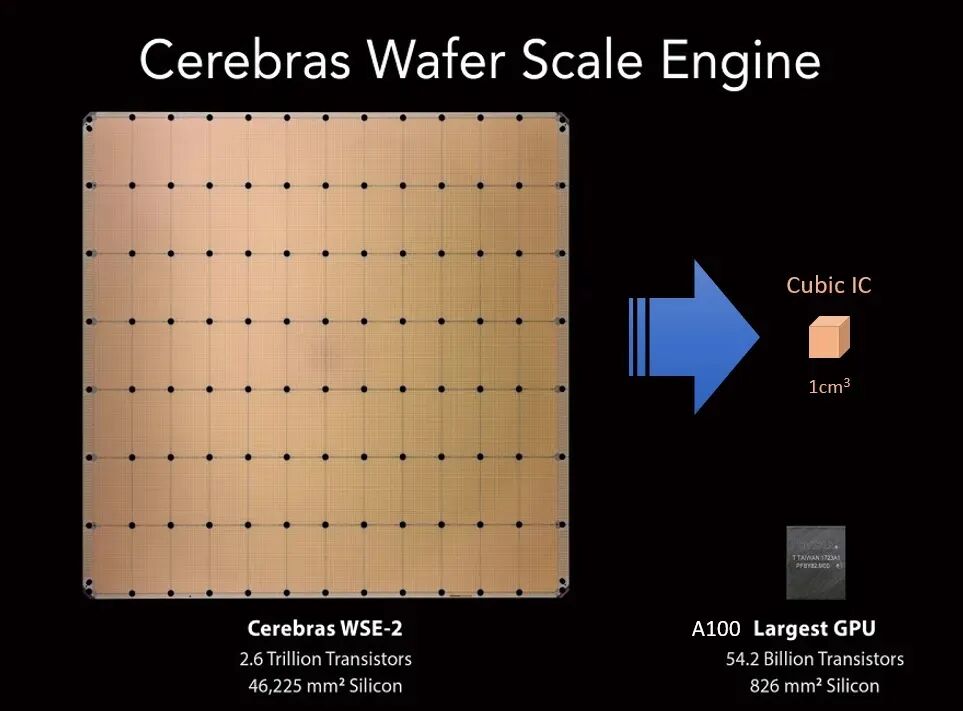

CIC (Cubic Integrated Circuit) is a concept I proposed in an article titled “New Ideas in Integrated Circuit Design” on August 7, 2021, aimed at designing chips with a cubic approach.Here, I want to emphasize that CIC is planned and designed with a cubic approach from the beginning, as shown in the diagram below, where an SoC is initially planned to be designed with 4 layers or more, requiring sufficient functional support from EDA vendors in software development to achieve. In practical applications, CIC could have 10, 20, 50, 100, 500 layers, or more. From the perspective of the fastest signal arrival and energy conservation, a perfect cube is the optimal chip shape, which is the origin of the CIC name.With the current 7nm process, over 10 billion transistors can be integrated on a chip the size of a fingernail. If designed in the CIC model, the number of transistors that can be integrated within a cubic centimeter the size of a fingertip would be 250 trillion to 500 trillion, which is 250 to 500 times that of 10 billion.If CIC can be realized, the largest chip in the world today, the WSE second-generation chip, which is the size of a dinner plate and has 2.6 trillion transistors, could be fully realized within a cubic centimeter the size of a fingertip according to the CIC design approach.

In practical applications, CIC could have 10, 20, 50, 100, 500 layers, or more. From the perspective of the fastest signal arrival and energy conservation, a perfect cube is the optimal chip shape, which is the origin of the CIC name.With the current 7nm process, over 10 billion transistors can be integrated on a chip the size of a fingernail. If designed in the CIC model, the number of transistors that can be integrated within a cubic centimeter the size of a fingertip would be 250 trillion to 500 trillion, which is 250 to 500 times that of 10 billion.If CIC can be realized, the largest chip in the world today, the WSE second-generation chip, which is the size of a dinner plate and has 2.6 trillion transistors, could be fully realized within a cubic centimeter the size of a fingertip according to the CIC design approach. This is undoubtedly a qualitative leap; however, the design and manufacturing of CIC will be a very challenging goal to achieve.To succeed in competition, one must overcome various difficulties and strive towards the established goals! This is the power of goals. Some people believe because they see, while others see because they believe.

This is undoubtedly a qualitative leap; however, the design and manufacturing of CIC will be a very challenging goal to achieve.To succeed in competition, one must overcome various difficulties and strive towards the established goals! This is the power of goals. Some people believe because they see, while others see because they believe.

Review and Outlook

The SoC technology began in the mid-1990s and emerged as a major direction in the transition from integrated circuits (IC) to integrated systems (IS), a necessary product of the development of integrated circuit technology to a certain extent. Motorola’s FlexCore, released in 1994, is said to be one of the earliest products realized through SoC technology.SoIC technology was officially proposed by TSMC in 2018, integrating multiple independent small chips into a cohesive SoC system through 3D manufacturing technology, achieving higher functional density, lower communication latency, and lower energy consumption per unit. Currently, SoIC technology can be stacked up to 12 layers.The CIC concept was proposed in August 2021 and is still just an expectation for the development of chip technology, which may see significant and rapid advancements in the future.In existing chip technology, transistors are the basic unit for recording information and also the basic unit of functionality. In system space, the density of transistors also represents functional density. Whether it is SoC, SoIC, or CIC, the main purpose of their realization is to improve the functional density within the system space and reduce the energy consumption per unit of information transmission.SoC is proposed and led by design companies, SoIC is proposed and advocated by foundry manufacturers, while CIC will be proposed and promoted by EDA vendors. Let us wait and see!

END

The reproduced content only represents the author’s views

It does not represent the position of the Semiconductor Institute of the Chinese Academy of Sciences

Editor: Yi Er

Editor-in-Chief: Six Dollar Fish

Submission Email: [email protected]

Previous Recommendations

1. Understanding Silicon Photonic Communication Chip Co-packaging (CPO) Technology

2. High-K Materials in Chip Manufacturing

3. How to Avoid Burning RF PA?

4. Reliability Testing Structure Design – Proportional Reduction Rules

5. What is a Phase Object?