Published: 2020-04-17 | Source: Guangdong Plastic Network – Guangdong Plastic Industry Association | Edited: gdpia

PC engineering plastics are high molecular polymers that contain carbonate groups in their molecular chains. They can be classified into various types based on the structure of the ester groups, including aliphatic, aromatic, and aliphatic-aromatic types. Currently, they are the fastest-growing general engineering plastics among the five major engineering plastics, and modified PC engineering plastics are widely used in various fields.

Characteristics of PC Engineering Plastics

PC is colorless and transparent, heat-resistant, impact-resistant, and has a flame retardant rating of UL94 V-0. It exhibits good mechanical properties within normal usage temperatures. PC has excellent impact resistance, high refractive index, and good processing performance, achieving UL94 V-0 flame retardant performance without the need for additives. The main performance deficiencies of PC include insufficient hydrolytic stability, sensitivity to notches, poor resistance to organic chemicals, and low scratch resistance. Prolonged exposure to ultraviolet light can cause yellowing. Like other resins, polycarbonate is also susceptible to erosion by certain organic solvents. Polycarbonate has poor wear resistance, and some polycarbonate components used in wear-prone applications require special surface treatments.

Processing Conditions for PC Engineering Plastics

PC engineering plastics have excellent comprehensive performance, making them particularly suitable for manufacturing small components with precise dimensions, complex shapes, and light loads or minimal impact loads. During processing, viscosity decreases with increasing temperature, necessitating strict control over the three main conditions: raw material drying, injection temperature, and mold temperature.

Injection Pressure for PC Engineering Plastics

The impact of injection pressure on the performance of components is mainly reflected in the holding pressure time. A short holding pressure time can lead to shrinkage of the component or the formation of shrinkage voids and vacuum bubbles. Extending the holding pressure time, especially for large-area thick-walled components, can increase their density, eliminate vacuum bubbles, and improve dimensional stability. However, excessive holding pressure time can induce internal stress in the component, making it prone to cracking.

Applications of Modified PC Engineering Plastics

PC engineering plastics can be modified according to different application fields to meet corresponding material performance requirements. Modified PC engineering plastics are widely used in electronics, optics, medical devices, and mechanical equipment.

Optical Lighting Field: PC materials are used in the LED lighting sector, manufacturing large lampshades, protective glass, and eyepiece tubes for optical instruments, and are also widely used in transparent materials on aircraft.

Electronics and Electrical Field: PC materials are excellent E (120°C) grade insulating materials, used to manufacture insulated connectors, coil frames, tube bases, insulating sleeves, telephone housings and parts, and battery housings for mining lamps. They can also be used to produce highly precise components, such as CDs, telephones, computers, video recorders, telephone exchanges, and signal relays in communication equipment. PC films are also widely used as capacitor insulation, recording tapes, and color video tapes.

Mechanical Equipment Field: Modified PC materials are used to manufacture various gears, racks, worm gears, worm screws, bearings, cams, bolts, levers, crankshafts, and ratchets, and can also be used for protective covers, enclosures, and frames of mechanical components.

Medical Devices Field: PC materials can be used for medical cups, tubes, bottles, dental instruments, pharmaceutical containers, and surgical instruments, and can even be used for artificial organs such as artificial kidneys and lungs.

Modified PC Engineering Plastics from JUSAILONG

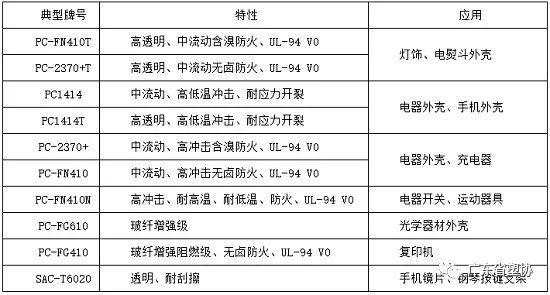

JUSAILONG’s modified PC engineering plastics mainly include flame-retardant PC, reinforced PC, high-flow flame-retardant PC, toughened PC, and light-diffusing PC.

Flame-retardant PC: The material’s flame-retardant performance meets industry standards UL94 V0/1.5mm; it has passed UL certification in the USA; it can withstand a free fall impact of 1.3m/500g steel ball; welding can pass free fall tests; environmental performance meets ROHS, halogen-free, Reach, and other industry regulations; the heat distortion temperature (1.82MPa/3.20mm) reaches 127°C. It is mainly used in high-end chargers, lamp holders, switch panels, and OA equipment in electronic and electrical products.

High-flow Flame-retardant PC: The material has good flowability, is easy to mold, has a small molding shrinkage rate, good toughness, can be spray-coated, and can be laser-engraved; it has good flame-retardant properties, reaching UL V0/1.5 level. It is mainly used in three-proof mobile phones, tablet back covers, and all-in-one computer back covers.

Reinforced PC: The material features low fiber float, good chemical resistance, high spray oil yield, and a good balance of rigidity and toughness, making it suitable for mobile phone frames, printers, copiers, cameras, learning machines, and optical equipment housings. Typical grades from JUSAILONG include PC-FG610, PC-FG410, etc.

Toughened PC: The material has good impact resistance; impact performance can be adjusted; it has a small molding shrinkage rate and stable dimensions; good weather resistance, high low-temperature impact; can be spray-coated. It is mainly used in thin-walled products, automotive parts, and electronic and electrical products.

Light-diffusing PC: The material features high light transmittance, high haze, and V0 flame retardancy, mainly used in extruded lamp tubes for LED lights, light-diffusing panels, injection-molded bulbs for LED lights, and lampshades.

UL Certified PC Engineering Plastics

With the increasing awareness of environmental protection and safety, the application of halogen-free flame-retardant materials is becoming more common. JUSAILONG PC-2370+T is a halogen-free flame-retardant PC engineering plastic with high glow wire and high CTI, certified by UL Yellow Card, ROHS, CQC, etc., and is used in sockets, switch panels, chargers, and charging pile housings.

Overview of Applications for JUSAILONG Modified PC Engineering Plastics: