Get More IIoT Insights

Click the blue text

Follow us

Rainbow Science

IIoT

Rainbow Science Case in Automotive Manufacturing

—— Daimler Applies HiveMQ to Ensure Automotive Production Processes

Introduction

Daimler AG, headquartered in Stuttgart, Germany, is the world’s largest commercial vehicle manufacturer and the leading luxury car producer, as well as the second-largest truck manufacturer. The company includes four major business units: Mercedes-Benz cars, Mercedes-Benz vans, Daimler trucks, and Daimler financial services.

Rainbow Science Case

Background

01

Rainbow Science · MQTT Broker Case

Background Introduction

Daimler’s manufacturing process includes a critical step of configuring and testing the electronic devices used to control Mercedes-Benz vehicles. Each Mercedes-Benz car has approximately 70-100 electronic control units (ECUs) for operating functions such as brakes, lights, locks, and entertainment systems. Daimler has created a Vehicle Diagnostic System (VDS) to coordinate the debugging and testing of these control units during production. The production of ECUs generates a large amount of data that needs to be transmitted to the IT department for further analysis and application.

The Vehicle Diagnostic System (VDS) is a key component in the automotive manufacturing process, as a failure lasting over 10 minutes can lead to a halt in the production line. This is because the VDS performs several core functions during the manufacturing of automotive electronic/electrical components, such as calibrating sensors controlled by ECUs, quickly displaying new firmware, personalizing car keys, and testing to ensure each ECU operates correctly, while also generating test documents required by the destination country’s regulations.

Rainbow Science · MQTT Broker Case

Technical Challenges

Challenges

02

Networks in factories are often unstable, which makes the connectivity of devices in the factory unreliable. Additionally, VDS testing equipment often needs to be moved within the factory workshop, which can frequently lead to network disconnections. As mentioned earlier, if the VDS fails for more than 10 minutes, it may cause the assembly line to stop, so minimizing the impact of network conditions on data transmission is crucial.

In summary, Daimler faces the following challenges:

-

Ensuring that the VDS does not fail;

-

A reliable information transmission platform is needed to connect factory data to the cloud;

Application

03

Rainbow Science · MQTT Broker Case

Case Application

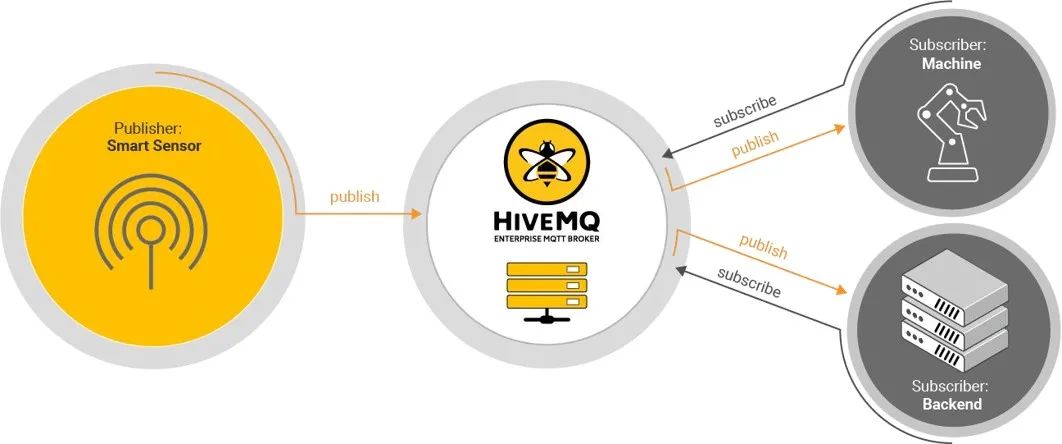

The advantage of the Rainbow HiveMQ solution lies in its simple and lightweight protocol, which provides a fast, efficient, and straightforward way to share information between the factory workshop and the enterprise IT systems.

MQTT pub/sub ensures that testing devices can continue to operate normally during network disconnections and reconnections. Daimler ultimately decided to use the MQTT protocol and adopted the HiveMQ broker provided by Rainbow Science as the core infrastructure service for its Vehicle Diagnostic System (VDS) to manage the information flow between the testing devices in the factory workshop and their enterprise IT systems on the server side.

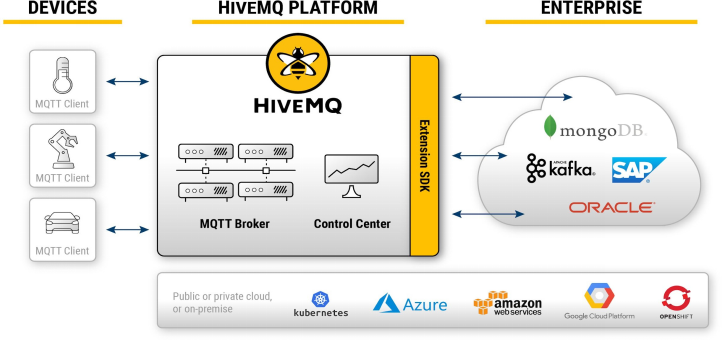

Each instance of the VDS includes multiple testing devices in the factory workshop, which connect to the HiveMQ broker located in the factory. On the server side, a series of microservices connect to the HiveMQ broker as MQTT clients. These microservices serve as front ends for various information databases and enterprise IT systems, which are necessary for completing the debugging and testing of the automotive VDS.

Daimler uses VDS across its 24 global factories, with approximately 10,000 testing devices connected to the VDS, sending 166 messages per second, totaling nearly 470 million messages transmitted via the HiveMQ broker each month.

Why Choose HiveMQ?

Initially, Daimler considered using AMQP and OPC UA but soon found these protocols too complex and burdensome for their needs. Additionally, unlike HTTP, MQTT supports broadcasting messages, which is extremely useful when the VDS needs to communicate with all testing devices. Daimler also considered solutions like Mosquitto or RabbitMQ but ultimately chose Rainbow HiveMQ broker for its professional enterprise support and maintenance services.

“We wanted a solution that could provide maintenance, testing, and support. The HiveMQ team impressed us from the start. They responded quickly to our questions and requirements and provided high-quality products.”

—— VDS Chief Architect Jochen Vajda

Today, the HiveMQ broker provided by Rainbow Science has been running in Daimler’s VDS for over four years, and Daimler is very satisfied with the reliability and stability of the HiveMQ platform. Marius Hertfelder from the VDS operations department said: “We have been running VDS with HiveMQ for 4 years, and the HiveMQ broker has never failed. When we need to restart the HiveMQ broker for any reason, the restart process is quick, and downtime is minimal. This is especially important because we cannot stop the assembly line in the factory; HiveMQ provides the stability and reliability our system needs.”

The MQTT pub/sub protocol ensures that testing devices can continue to operate normally during network disconnections and reconnections, so Daimler ultimately adopted the MQTT protocol, specifically the Rainbow HiveMQ broker, as the core infrastructure service for its Vehicle Diagnostic System (VDS) to manage the information flow between the testing devices in the factory workshop and their enterprise IT systems on the server side.

Rainbow Science · MQTT Broker Case

Introduction to HiveMQ

Solutions

04

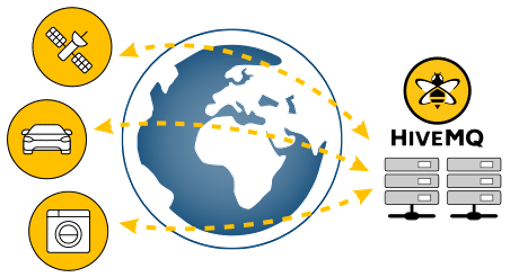

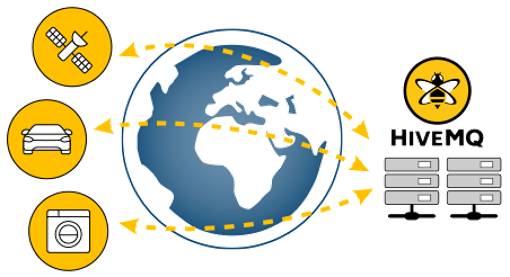

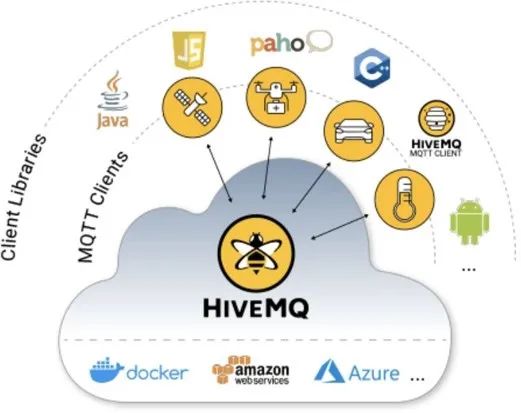

HiveMQ is a communication platform based on MQTT data transmission, designed to deliver data quickly, efficiently, and reliably to connected IoT devices. HiveMQ utilizes the MQTT protocol for real-time, bidirectional data pushing between devices and enterprise platforms.

HiveMQ was established to address some key technical challenges that enterprises face when building new IoT applications, including:

-

Building reliable, scalable critical business IoT applications

-

Fast data delivery to meet end-user expectations for responsive IoT products

-

Reducing operational costs by effectively utilizing hardware, network, and cloud resources

-

Integrating IoT data into existing enterprise systems

HiveMQ offers free, professional, and enterprise MQTT Broker products, and provides three enterprise-level extension suites for Kafka, enterprise security, and MQTT Broker bridging, along with efficient MQTT clients and cloud platforms to meet user needs comprehensively.

Rainbow Science – Industrial IoT

Rainbow Science is a high-tech company with over 3 years of experience in the Industrial IoT (IIoT) industry, collaborating with top companies worldwide including EXOR, Eurotech, Unitronics, Matrikon, KUNBUS, VDOO, Esper, etc., providing advanced high-end Industrial 4.0 industrial touch screens, high-end edge computers, IoT development frameworks, PLC and HMI integrated machines, OPC UA, industrial Raspberry Pi, SCADA, predictive maintenance solutions. All members of the IoT division are professionally trained and certified, with an average of over 3 years of technical experience, consistently earning excellent reputations from clients. We actively participate in industry associations, making significant contributions to the promotion of advanced technology. To date, Rainbow Science has provided various solutions ranging from hardware to software for numerous users in the industry and has participated in and assisted many OEM equipment development and migration projects, as well as smart factory and Industrial 4.0 upgrade projects for end-users.

Long press to recognize the QR code below// Get insights without getting lost

Rainbow Science Industrial IoT Group Chat

Follow Rainbow Science for more cutting-edge IIoT knowledge

Past Issues

Highlights

RevPi Application Case · Here

● Use CloudRai.Box to quickly upload sensor data to the cloud in just 4 steps

● How to achieve conversion between industrial protocols and MQTT in a low-code/no-code manner?

● Five potential uses of industrial Raspberry Pi as a soft PLC

● How industrial Raspberry Pi combined with CODESYS easily solves three major challenges facing IIOT

Edge Computing · What Do You Know?

● Want to achieve device servitization? You need a powerful edge device!

● What is the machine-as-a-service model?

● What characteristics should HMI for the food and pharmaceutical industry have?

● Application of smart industrial control screen eX707 in underwater remote-controlled robots

What You Want to Know · OPC UA

● How to solve the headache of DCOM configuration

● Step-by-step guide to mastering all your UA servers with the OPC UA data platform

Powerful Data Collection and Monitoring System · mySCADA

● Example of upgrading and transforming myBOX sewage treatment automation and control

● Example of remote monitoring for smart buildings/homes

Predictive Maintenance · SIAI

● Helping hard disk manufacturers improve quality and efficiency in manufacturing processes

● Proven predictive maintenance is done this way!