The control systems of the 21st century will be a combination of networking and control.The study of Networked Control Systems (NCS) has become one of the cutting-edge topics in the field of automation.Communication networks embedded as a link in control systems have greatly enriched industrial control technologies and methods, causing significant changes in the system structure, control methods, and human-machine collaboration between automation systems and industrial control systems.At the same time, new issues have arisen, such as the coupling of control and communication, delays, and information scheduling.Methods, distributed control modes, and faults.

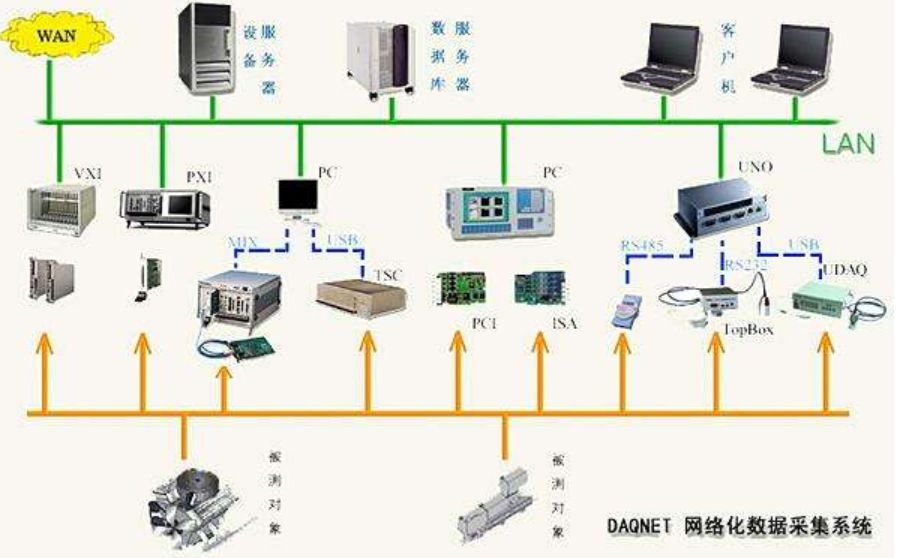

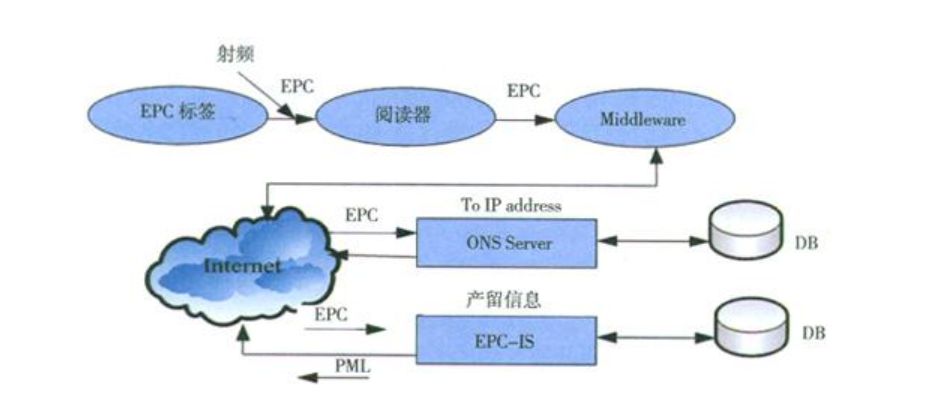

With the emergence of these new issues, the control methods and algorithms of automatic control theory in a networked environment need continuous innovation. With the development of computer technology, communication technology, and network technology, the traditional control field is beginning to evolve towards networking.A Networked Control System refers to a control system where the components of the control loop exchange data through a communication network.Its characteristic is that the commands and feedback of the control system are transmitted over the network in packet form.The most important feature of a Networked Control System is the connection between cyberspace and physical space, allowing many tasks to be executed over long distances.

Moreover, the signals in Networked Control Systems are transmitted through shared networks (and wiring), eliminating unnecessary wiring, reducing system complexity, and lowering the costs required for design and installation.If sensors, controllers, or actuators need to be added to adjust or update the system, it can also be done at a lower cost without changing the main architecture of the system.The greatest feature of Networked Control Systems is that each controller can efficiently share data, allowing for the integration of overall information in a large physical space to make informed decisions.

Networked Control Systems can be applied in many fields, such as space and land exploration, entering hazardous areas and related operations, factory automation, remote diagnosis and troubleshooting, experimental equipment, home robotics, aircraft, vehicles, factory monitoring, care centers, and remote operations.However, while there are many theoretical applications for Networked Control Systems, there are few practical cases until the concept of Industry 4.0 has gained increasing attention, and this technology is gradually being recognized.

First, the traditional control field is undergoing unprecedented changes, beginning to evolve towards networking.The structure of control systems has developed from Computer-Controlled Systems (CCS) to the second generation of Distributed Control Systems (DCS), and then to Fieldbus Control Systems (FCS).The demands for large data volumes and high-speed transmission, such as image and voice signals, have also spawned the combination of industrial Ethernet and control networks.

Second, this trend of networking in industrial control systems integrates many popular technologies, including embedded technology, multi-standard industrial control network interconnection, and wireless technology, expanding the development space of the industrial control field and bringing new development opportunities.However, the most critical and important issue for decentralized Networked Control Systems is to meet the requirements for system reliability and dependency, and to ensure high performance within its working range, which has become increasingly complex.Therefore, the detection and diagnosis of networked errors are receiving increasing attention, and these are also core aspects of monitoring system performance in industrial scenarios.

Advancing industrialization through information technology is a powerful guarantee for the sustained and rapid development of the national economy and an important means for the transformation of the traditional industrial system structure.As a representative of information technology, the combination of network technology and industrial control systems will greatly enhance the level of control systems, change the relatively closed enterprise information management structure of existing industrial control systems, and adapt to the needs of modern enterprise comprehensive automation management.Network technology promotes the transformation of traditional industrial control system structures.

The significance lies in the integration of fieldbus, Ethernet, various industrial control network interconnections, embedded technology, and wireless communication technology in industrial control networks, which not only ensures the original stability and real-time control system requirements but also improves the openness and interoperability of systems, enhancing their adaptability to different environments.In today’s era of economic globalization, this kind of industrial control system network and its composition model enables enterprises to adapt to unprecedented fierce market competition, helps accelerate the development of new products, reduces production costs, and improves information services, offering broad development prospects.

Disclaimer: This article is a network reprint, and the copyright belongs to the original author. However, due to the numerous reprints, it is impossible to confirm the true original author, so only the source of reprint is indicated. If any videos, images, or text used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or delete the content immediately! The content of this article reflects the original author’s views and does not represent the views of this public account or its responsibility for its authenticity.