Case Study by Daheng Imaging

LCD Backlight Module Defect Detection

Basic Case Information

Industry: Flat Panel Display Industry

Project: LCD Backlight Module Defect Detection

Technology Type: Defect Detection

Case Background

LCD (Liquid Crystal Display) is a mainstream display technology due to its superior overall performance, suitable for terminal display applications of various sizes. The backlight module, as a key component of LCDs, provides sufficient brightness and evenly distributed light sources for normal image display. The performance of the backlight module directly affects the image quality of the LCD.

Traditional inspection relies on manual defect screening. For objective defects like horizontal lines, vertical lines, bright spots, and dust spots, manual inspection can be done visually or with a magnifying glass. However, subjective defects like optical uniformity and shadows are influenced by the inspector’s subjective awareness, making it difficult to quantify standards based on personnel experience. Therefore, machine vision technology was introduced to perform defect detection on the backlight module’s display surface, replacing the original manual inspection method. This avoids missed or incorrect inspections due to eye fatigue and achieves faster detection. For subjective defects like uniformity, quantitative detection can also be performed, effectively preventing defective products from flowing into downstream assembly as finished products.

Case Requirements

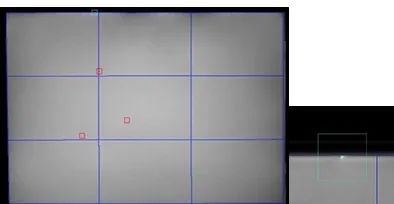

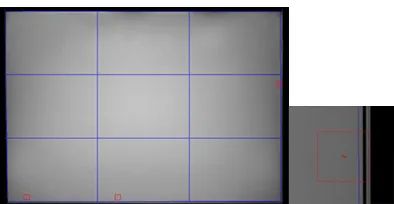

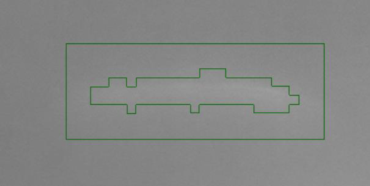

The detection field of view needs to cover products sized 7.85″ to 12.9″, detecting oversized black/white point defects on the surface after self-luminous display, including bright spots, edge bright spots, foreign objects, fluff, black contamination, large area pollution, and scratches, as well as achieving optical uniformity detection.

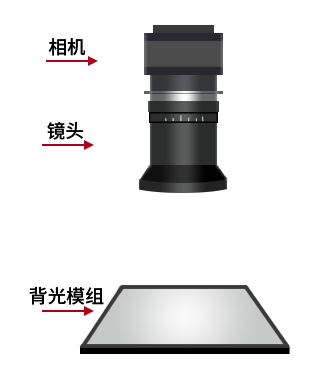

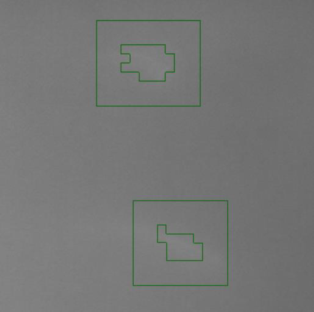

Visual System Schematic

Case Overview

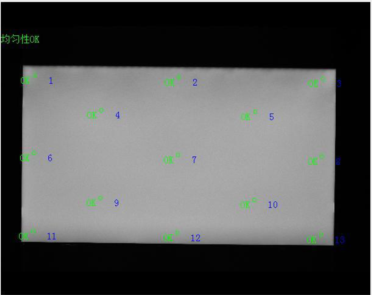

The defect detection system for backlight modules designed by Daheng Imaging uses the Vieworks large-area area array camera and Linos large-area lens for imaging, combined with the professional image processing software HALCON from Germany. Through image marking training, precise location and detection of defects are achieved.

Case Display

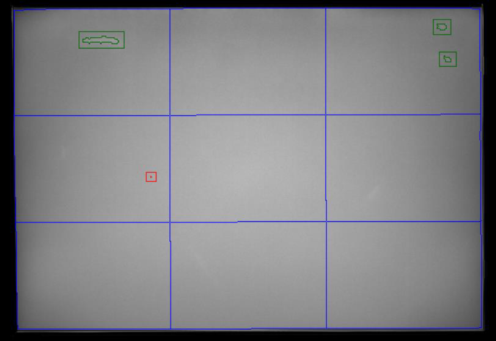

Through debugging the established system, the visual inspection system can detect defects larger than or equal to 0.02mm², meeting customer specifications such as a missed detection rate ≤ 1%, false positive rate ≤ 5%, and CT ≤ 6s. Currently, this visual inspection system is being used in batches by a well-known backlight module manufacturer.

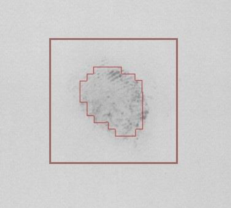

The detection results are illustrated as follows: Swipe left and right to see more

Bright Spots

Edge Bright Spots

Fluff

Black Contamination

Foreign Objects

Large Area White Pollution

Large Area Black Pollution

Uniformity Detection

Related Product Recommendations

The Vieworks VC series cameras are designed for imaging system applications requiring high resolution, high speed, and long-distance transmission. The cameras are widely used in printed circuit board inspection, semiconductor wafer inspection, flat panel display inspection, solar panel inspection, and other applications.

The Qioptiq Linos Rodagon series is suitable for large format sensors and line scan applications. Rodagon high-performance lenses provide high-quality and stable images while achieving high magnification.

Schneider EMERALD series lenses are suitable for large area cameras, covering a wide range of working distances. The robust mechanical and focal length locking devices ensure maximum stability even in harsh environments, suitable for 2D/3D measurement, optical automatic inspection, and traffic and monitoring.

MVTec HALCON is a powerful standard machine vision software with an integrated development environment that can save development costs and shorten software development cycles. HALCON fully supports multi-core platforms and special instruction sets (such as AVX2 and NEON), as well as GPU acceleration.

Customized Visual System Services

Daheng Imaging has been focused on the machine vision industry since its establishment in 1991, adhering to the concept of “continuous innovation.” Following this concept, Daheng Imaging has successfully provided high-quality products and customized visual solutions for customers in various industries including consumer electronics, renewable energy, semiconductors, automotive, logistics, transportation, pharmaceuticals, and scientific research.

Perhaps your industry is also facing the challenge of “increasing speed and efficiency.” If you are at a loss regarding the current “speeding up and increasing efficiency” process, please contact Daheng Imaging immediately: 400 999 7595. We will provide you with: professional technical consultation and project evaluation in the early stage, product selection and targeted development in the mid-stage, and system deployment and technical training in the later stage. Our one-stop service will alleviate your worries and assist your industrial upgrade!

Contact Information

Hotline: 400-999-7595

Daheng (Group) Co., Ltd. Beijing Imaging Vision Technology BranchWebsite: www.daheng-imaging.com Email: [email protected] Headquarters Address: 12th Floor, North Building, Daheng Technology Tower, No. 3 Suzhou Street, Haidian District, Beijing (100080) Switchboard: 010-82828878

Shenzhen OfficeAddress: 8th Floor, Block B, Longguang Century Building, No. 23 Haixiu Road, Bao’an District, Shenzhen (518101) Phone: 0755-83479565Shanghai OfficeAddress: Room 1808, Hongxing World Trade Building, No. 598 Nujiang North Road, Putuo District, Shanghai (200333) Phone: 021-35312826Wuhan OfficeAddress: Room 2009-2010, Block A, Optical Valley Times Square, No. 111 Guanshan Avenue, Hongshan District, Wuhan (430079) Phone: 027-87223690Xi’an OfficeAddress: Room 1601, Block F, Wangzuo Modern City, No. 35 Tangyan Road, High-tech Zone, Xi’an (710065) Phone: 029-89521122Chengdu OfficeAddress: Room 803-1, Building B, No. 5 Chengyi North Street, Software Park Phase III, Jimei District, Xiamen (610021) Phone: 028-86925034

Xiamen Office

Address: Room 803-1, Building B, No. 5 Chengyi North Street, Software Park Phase III, Jimei District, Xiamen

Phone: 0592-5500803

Hong Kong, Macau, Taiwan, and Overseas (Daheng Imaging Cameras & Lenses)

Phone: 010-82828878-8081

Email: [email protected]

Northeast Region AgentHarbin Sanhe Micro-Nano Technology Co., Ltd. Address: Room 1617, Electronic World, Jiao Hua, Nangang District, Harbin (150001) Phone: 0451-86262530

← WeChat Official Account

↓ Douyin Official Account